Latest News

2025

15th December 2025 - Season's Greetings From Amber Industries

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities. We look forward to working with you in 2026.

Read More

Read More

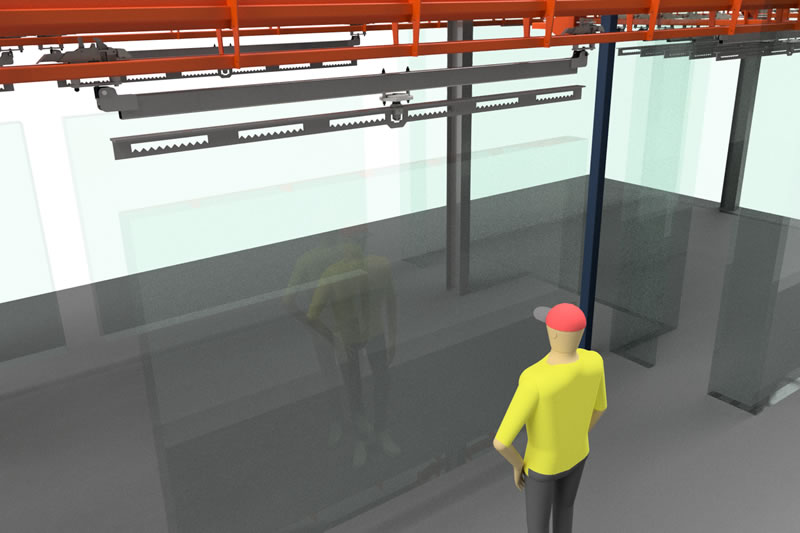

4th December 2025 - Control Systems For Overhead Conveyor Automation

Just as crucial to the efficient functioning of any conveyor system as the mechanical hardware is its control system. Depending upon the complexity of the conveyor system, control systems can range from simple start stop boxes to multiple control panels incorporating state-of-the-art PLCs and HMI’s regulating numerous input and output devices. Find out more at https://www.amber-industries.ltd.uk/

Read More

Read More

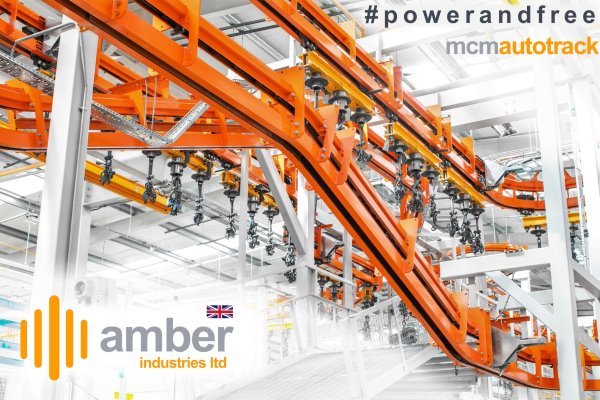

4th November 2025 - MCM Powertrack Range From Amber Industries

MCM Powertrack - A range of ‘monorail’ overhead chain conveyors suitable for handling a wide range of products in many industries. They come in two types: the ‘enclosed chain’ type for medium loads up to 100Kg and the ‘open chain’ type for heavier loads up to 500Kg. Find out more at https://www.amber-industries.ltd.uk/mcm-powertrack.

Read More

Read More

13th October 2025 - MCM Freetrack Conveyor Systems In Focus

MCM Freetrack conveyor systems use the standard track components available in the Powertrack range, however instead of fitting a chain powered by a motorised drive unit, free running trolleys (bogies) are inserted into the system from which the product load is suspended. Find out more at https://www.amber-industries.ltd.uk/news.

Read More

Read More

1st September 2025 - MCM Dualtrack Inverted Conveyor System

The MCM Dualtrack range of conveyors, DT100 & IAT100 P&F are comprised of a powered bi-planar chain in an enclosed track with a secondary stabilising rail forming another track, hence 'dual' tracks. They are very stable making them suitable for accurate positioning of the product. The IAT100 system is a true inverted Power & Free Chain Conveyor System.

Read More

Read More

13th August 2025 - Laundry Conveyors by Amber Industries

Amber Industries is experienced in engineering and delivering a full range of conveyor systems for moving linen around laundries. Parallel sorting conveyors requiring special treatment at the cross transfer sections at each end to allow loose linen to be recirculated efficiently without taking a lot of space. Special attention is paid to detailing to avoid frequent jams.

Read More

Read More

11th July 2025 - MCM Powertrack Overhead Monorail Conveyor Systems

A range of monorail overhead chain conveyors suitable for handling a wide variety of products in many industry sectors, e.g. automotive, surface finishing, food industry processing and general manufacturing. MCM Powertrack overhead conveyors come in two types: ‘enclosed chain’ for loads up to 100Kg, where the powered chain runs in a pressed steel enclosed track section and ‘open chain’ for heavier loads up to 500Kg where the chain is slung under a rolled steel I-section using trolleys. Find out more at https://www.amber-industries.ltd.uk/mcm-powertrack.

Read More

Read More

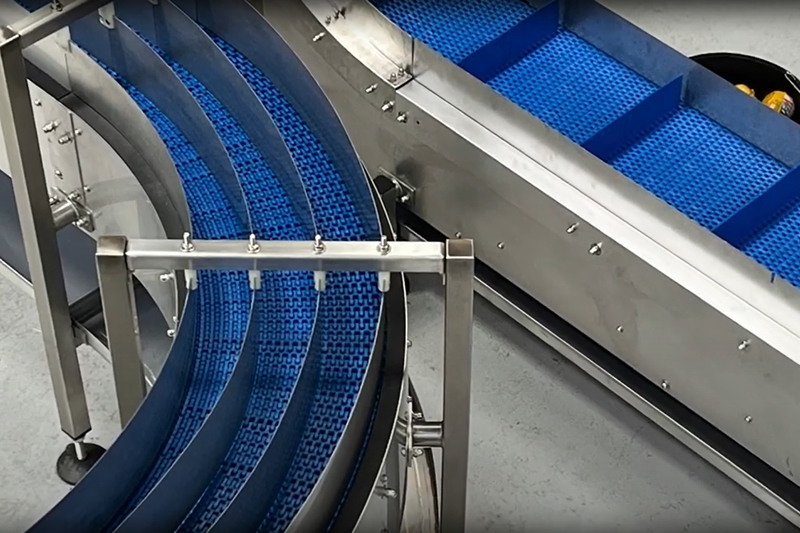

2nd June 2025 - Belt Curves for Airport Baggage Handling Systems

Gramac Quartz belt curves have a proven track record over 30 years of longevity and reliable operation in airport baggage handling systems around the world from remote islands in the Pacific to the largest and busiest airports.

Read More

Read More

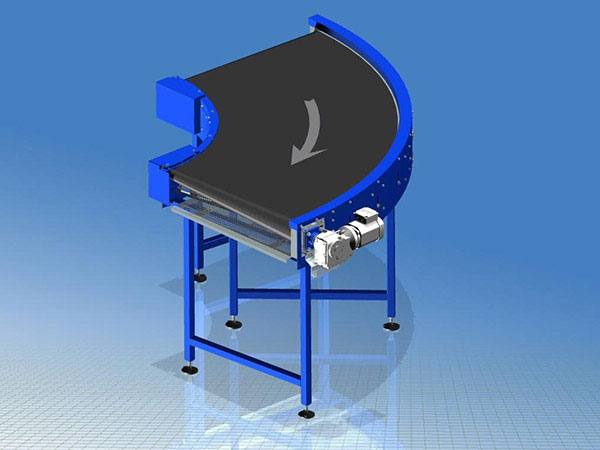

15th May 2025 - Belt Curves for the Manufacturing & Processing Industries

Gramac Quartz belt curves are used in many Industries where precise and fast changes in direction of conveyed products is required. Examples are in bulk material bagging lines (e.g. cement, aggregates, compost etc), car component production lines, food packaging lines and laundries to name just a few.

Read More

Read More

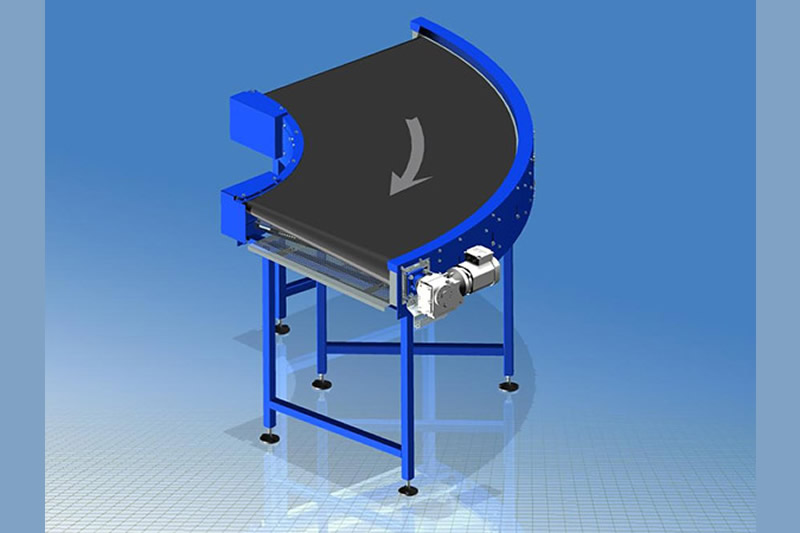

11th April 2025 - Belt Curves For The Intralogistics Industry In Focus

Amber Industries range of high speed, friction driven and robust belt curves are designed to reliably give the long service life demanded by the Intralogistics Industry. The Gramac Quartz division of Amber Industries has designed and manufactures the TSTR100 range of powered belt curve conveyors which includes a number of sizes and formats specifically suited to intralogistics applications such as warehouses, post and parcel sorting depots, and e-fulfilment centres.

Read More

Read More

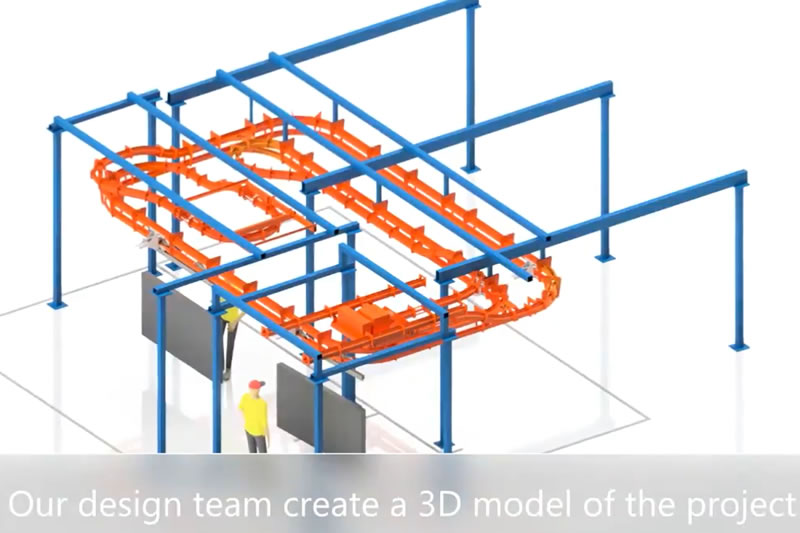

24th March 2025 - AT100 Power & Free Range Conveyor Project Underway

This is a recent project that we’re engineering, soon to be manufactured ready for installation in May. The conveyor is our AT100 Power and Free range, with a trolley load capacity of 100KG each. The dual Trolley load bar configuration offers a load capacity of 200KG with product dimensions up to 3000 mm in line, 2100 mm high and 200 mm wide with 360 degree indexing rotation. The system offers a super-efficient and compact design by utilising the Power and Free functionality with the side shuffle inside the oven and loading bay. More updates to follow.

Read More

Read More

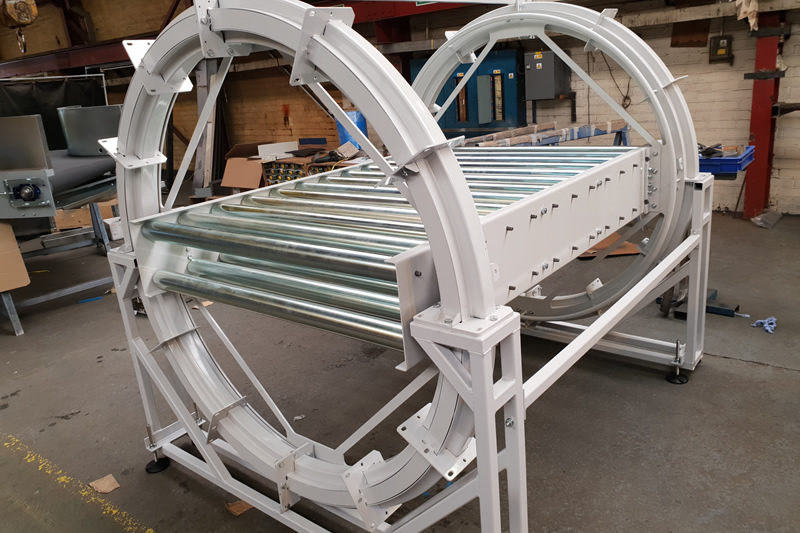

3rd March 2025 - Bespoke Handling Solutions

Amber Engineers designed, manufactured and installed this device for turning over delicate sheet materials to allow both sides to be surface treated. Amber Industries engineering team have the ability to design bespoke handling equipment to make a conveyor system function optimally. Find out more at https://www.amber-industries.ltd.uk/turnover-unit-bespoke-handling-solutions.

Read More

Read More

26th February 2025 - Amber Industries on Stand G10N at Surface World

Amber Industries on Stand G10N at Surface World, NEC Birmingham 26th and 27th February, We look forward to seeing you there. Amber Industries are exhibiting at the 2025 edition of Surface World between 26th and 27th February. Our booth number G10 in Hall 11 at the NEC in Birmingham. If you were waiting to visit the Surface World exhibition registration is now open. We look forward to seeing you this February at the NEC at #Surfaceworld2025. Click the link below for your visitor pass https://register.visitcloud.com/survey/1vgcgppqwt8m2

Read More

Read More

13th February 2025 - Visit Amber Industries At Surface World 2025

The exhibition is the UK’s only event dedicated to the surface treatment, product finishing and coatings industry. It provides a major showcase for the very latest technology and developments in this important and expanding area.

Read More

Read More

4th February 2025 - Bespoke Handling Solutions

Amber Industries engineering team have the ability to design bespoke handling equipment to make a conveyor system function optimally.

Read More

Read More

9th January 2025 - Conveyor Maintenance & Repair Services

With its own team of skilled installation and service engineers, supplemented by a nationwide network of professional site services contractors, Amber Industries Ltd. offers the full complement of support services needed to ensure minimum downtime and the maximum reliable operating lifespan of our client’s conveyor systems.

Read More

Read More

2024

9th December 2024 - Season's Greetings From Amber Industries

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. Our last working day before Christmas will be Tuesday 24th December 2024, reopening on Thursday 2nd January 2025. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Read More

Read More

5th November 2024 - Ancillary Equipment From Amber Industries

All types of conveyor equipment required can be specified into a turnkey floor conveyor system which can be configured and installed to operate most efficiently, Amber Automation can supply them. Demonstrated here is a selection of just some of the ancillary equipment that Amber Automation has within its product portfolio. Nearly all these types of equipment are designed and manufactured in-house which allows us to tailor them to the specific requirements of the floor conveyor system which they are a part of. Find out more at https://www.amber-industries.ltd.uk/ancillary-equipment.

Read More

Read More

2nd October 2024 - Steel Slat, Modular Plastic & Wire Mesh Belt Conveyors

The moving belts of each of these categories of conveyor have properties and features which make them suitable for particular applications. Whatever the particular application Amber Automation has a great deal of experience in designing, manufacturing and installing 'built for purpose' conveyor systems using these specialist belt types. Find out more at https://www.amber-industries.ltd.uk/steel-plastic-wire-mesh-conveyors.

Read More

Read More

3rd September 2024 - Amber Automation Pallet & Heavy Duty Chain Conveyors

Chain conveyors, sometimes referred to as drag chain conveyors, are comprised of; two, three or multiple strands of roller bush chain guided on parallel tracks. Find out more at https://www.amber-industries.ltd.uk/pallet-heavy-duty-chain-conveyors.

Read More

Read More

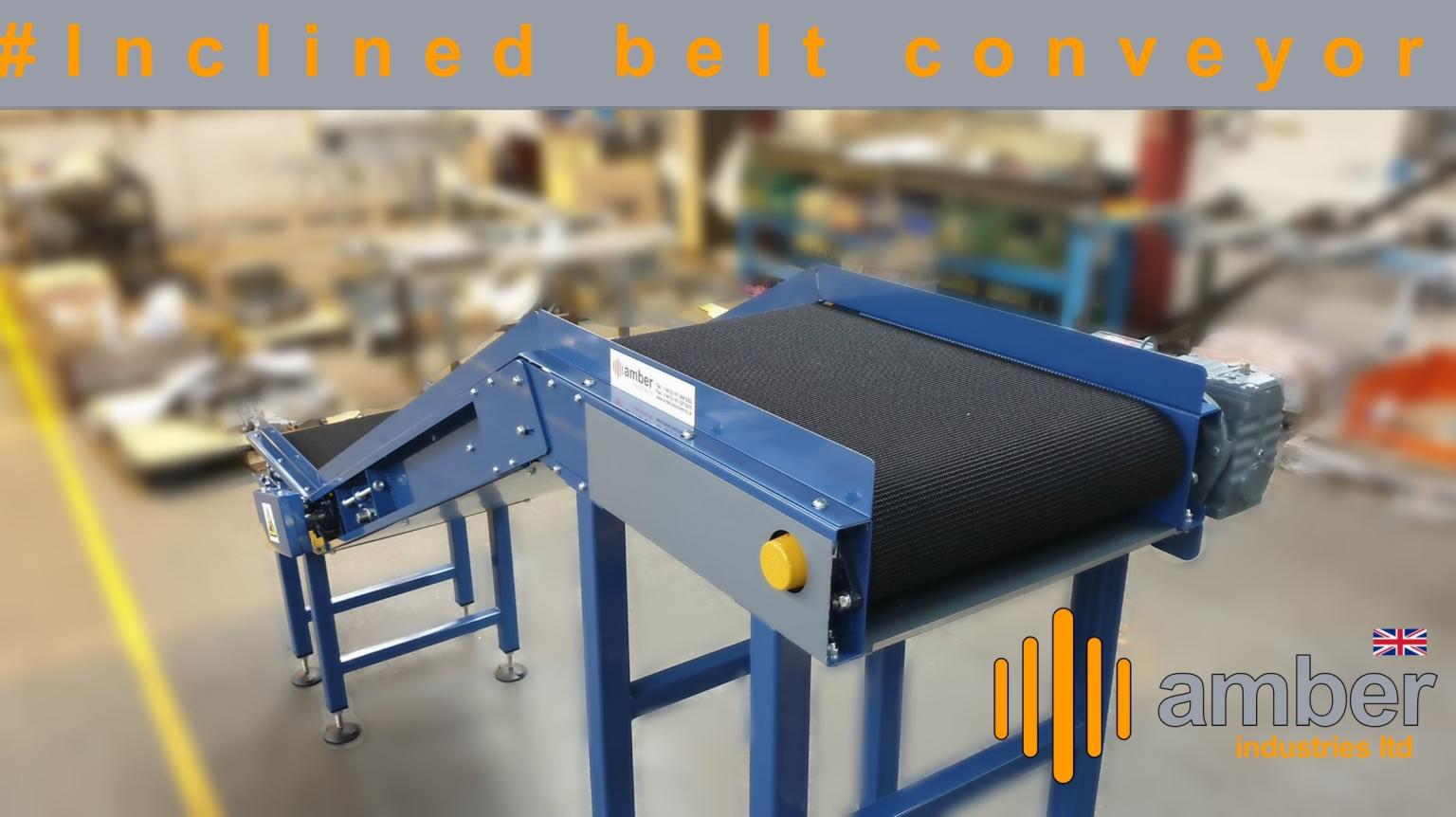

5th August 2024 - Amber Automation Level & Incline Belt Conveyors

Belt conveyor systems offer a solution for handling product loads which are irregular in shape and do not always have a rigid flat lower surface required for roller conveyors. They also have the advantage that they can be set on an incline or decline in order to change the elevation of the product load. Find out more at https://www.amber-industries.ltd.uk/level-incline-belt-conveyors.

Read More

Read More

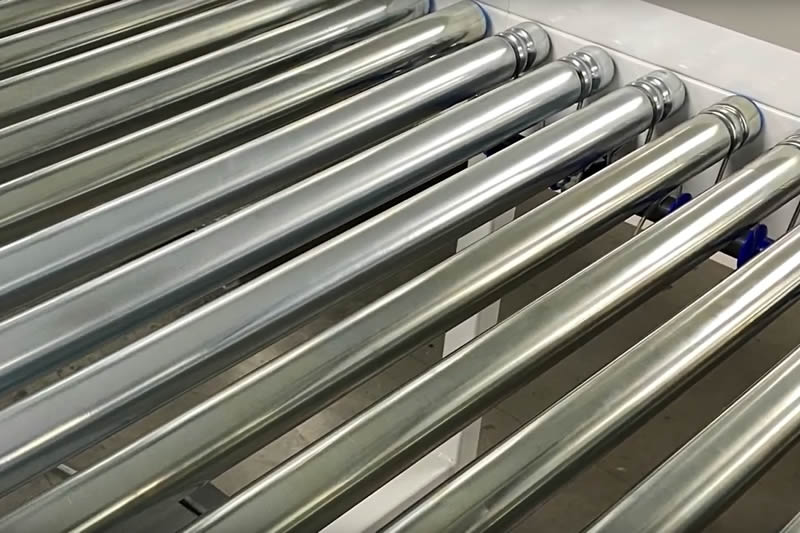

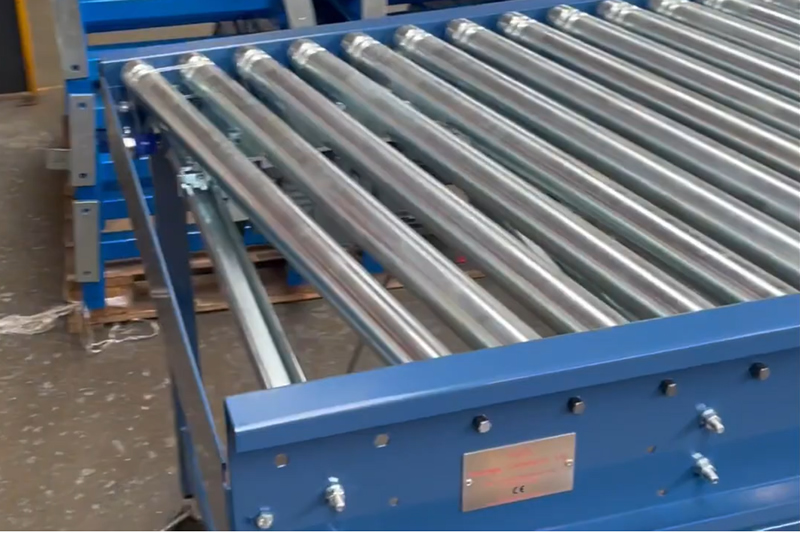

4th July 2024 - Amber Automation Powered & Gravity Roller Conveyor Systems

Roller conveyors are versatile and relatively low cost so they make up the main part of many unit load conveyor systems. They can be either free running relying on gravity to move the load or powered where the roller provides the motive force. Find out more at https://www.amber-industries.ltd.uk/power-gravity-roller-conveyors

Read More

Read More

6th June 2024 - MCM Autotrack Power & Free Conveyor Systems In Focus

A range of ‘power & free’ overhead chain conveyors designed with the flexibility to allow product to be directed along different routes within the same system depending upon the sequence of processes to be applied. Find out more at https://www.amber-industries.ltd.uk/mcm-autotrack

Read More

Read More

3rd April 2024 - Pet Food Product Modular Belt Conveyor System

Modular Belt Conveyor System - For handling pet food. This system incorporated a bespoke designed chute system, hopper and independently driven 3 lane divider (powered PU bands). This was to enable smooth feed into an automatic robot packing machine. Find out more at https://www.youtube.com/watch?v=RvM4M42jOaw

Read More

Read More

4th March 2024 - Powertrack Enclosed Chain Conveyor Systems

Powertrack Enclosed Chain Conveyor Systems - This range of conveyor systems incorporates the PT30, PT60, PT100 & PT100S. These systems consist of a bi-planar chain powered by a drive unit and running in an enclosed steel track which can either be rectangular in cross section or a cruciform shape where a higher load carrying capacity is required. Attached to the chain at regular pitches are pendants which protrude through a slot in the underside of the track and to which the product can be suspended. Find out more at https://youtu.be/7Zf-ZUGJR2c

Read More

Read More

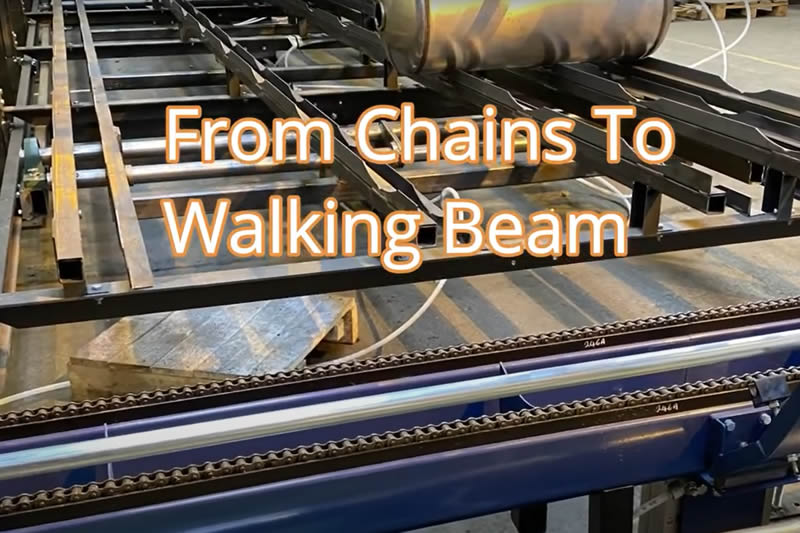

5th February 2024 - Twin Chain Conveyor & Walking Beam System

Twin Chain Conveyor & Walking Beam System - To buffer store cylinders, amber industries created a twin chain conveyor & walking beam system. Find out more at https://youtu.be/qgSvMlboEOY.

Read More

Read More

4th January 2024 - High Speed Mini Sortation System With 5 Destination Points

Amber Industries were asked to implement a high speed mini sortation system with 5 destination points. We chose a mixture of belt conveyors and 24v dc 90 degree transfer units. Client has an RFID system, so a reader was placed under the first belt conveyor, which signals its destination. Find out more at https://youtu.be/ba5hmOVg8vk

Read More

Read More

2023

15th December 2023 - Season's Greetings From Amber Industries

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. Our last working day before Christmas will be Friday 22nd December 2023, reopening on Tuesday 2nd January 2024. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Read More

Read More

2nd November 2023 - PVC Belt Conveyors Across Many Applications

Various PVC Belt Conveyors - Highlighting food, non-food, end drives, centre drives, transfers and various options, including under guarding and the use of castors.

Read More

Read More

3rd October 2023 - Visit Amber Industries At Surface World 2023

Amber Industries are exhibiting at the 2023 edition of Surface World between 4th & 5th October this week. Our booth number H2 in Hall 11 at the NEC in Birmingham. If you were waiting to visit the Surface World exhibition registration is now open. We look forward to seeing you this October at the NEC at #surfaceworld2023. Click the link below for your visitor pass https://register.visitcloud.com/survey/3qzh83sjzwmtz

Read More

Read More

4th September 2023 - Chain Driven Powered Roller Conveyor (Pallet)

A recent project from Amber Industries using pallet conveyor systems with AGV's (Automated Guided Vehicles) allows fully automated areas, therefore, no need for fork lift trucks or people. Watch the video at https://youtu.be/TQG1ieilyTs.

Read More

Read More

1st August 2023 - Overhead Conveyor (Drone Footage & Commissioning)

Demonstrating an overhead conveyor via drone footage. This gives a good understanding of what to consider preparing a layout, the track path and support structure/type. The video also offers a small glimpse of commissioning the system. Watch the video at https://youtu.be/w2A8nJp9P2o

Read More

Read More

17th July 2023 - Lineshaft Powered Roller Warehouse Conveyor System

Lineshaft Powered Roller Warehouse Conveyor System - Amber Industries demonstrating a simple straight line lineshaft powered roller conveyor system in a warehouse. Ideal & cost effective way of automating or semi automating distribution/packing lines.

Read More

Read More

7th June 2023 - Amber Industries Exhibiting At Surface World 2023

Amber Industries are exhibiting at the 2023 edition of Surface World between 4th & 5th October later this year. Our booth number H2 in Hall 11 at the NEC in Birmingham. If you were waiting to visit the Surface World exhibition registration is now open. We look forward to seeing you this October at the NEC at #surfaceworld2023. Click the link below for your visitor pass https://register.visitcloud.com/survey/3qzh83sjzwmtz

Read More

Read More

4th May 2023 - 24V DC ZLP Powered Roller Conveyors

24V DC Zero Line Pressure Powered Roller Conveyors - This video includes an example of a triple strand chain transfer (when orientation of product is either not important, or actually needs to change), and a 90 degree turntable (when orientation of product is important). These types of systems can be manipulated to suit the application. Find out more at https://youtu.be/8IM38YSGFeM

Read More

Read More

2nd April 2023 - PVC Belt Bend/Curve Conveyors

PVC Belt Bend/Curve Conveyors highlighting PVC belt bend conveyors, where a true bend is required (without straights on the infeed or outfeed) to fit between existing conveyors. Amber's Gramac quartz division have specialised for over 30 years in the manufacture of belt curves for many different combinations of load duty, arc and width formats. Find out more at https://youtu.be/j97tc_cqGqA

Read More

Read More

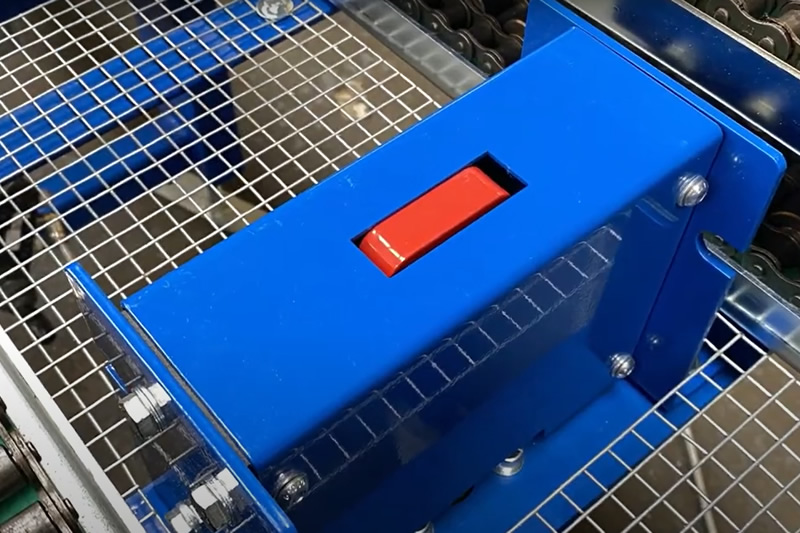

1st March 2023 - Bespoke Stop Unit For Accumulating Twin Chain

Bespoke Stop Unit For Accumulating Twin Chain - Amber Industries designed a bespoke stop unit for bespoke pallets for an accumulating twin chain conveyor system. The full system had 24 unique stop sets / singulation devices fitted. Find out more at https://youtu.be/i4Wk2OINez0

Read More

Read More

1st February 2023 - Gravity Roller Conveyors For The Furniture Industry

Gravity Roller Conveyors For The Furniture Industry - Amber Industries supply gravity roller conveyor systems to some of the largest furniture manufacturers in the UK. Gravity conveyors are predominantly used, as the products are so large, coupled with the need to be able to manipulate them as they are being assembled. Find out more at https://youtu.be/Sng4AB4HObc.

Read More

Read More

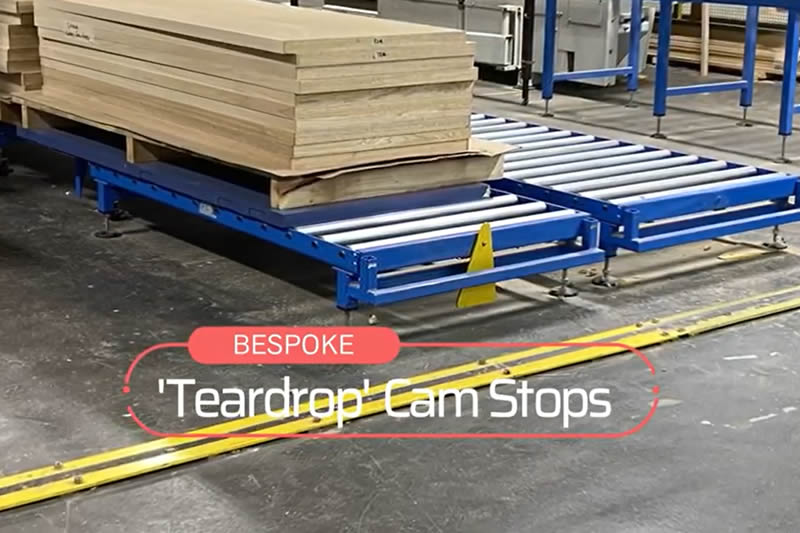

9th January 2023 - Gravity Roller Conveyor System for Stacks of Wooden Sheets

Amber Industries recently manufactured and supplied a bespoke gravity roller conveyor system for transporting stacks of wooden sheets from processing to end of line. With the inclusion of three traversing trollies separating work in progress and differing mid line operations. Find out more at https://youtu.be/_d-ubaXc2Xo

Read More

Read More

2022

9th December 2022 - Season's Greetings From Amber Industries

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. Our last working day before Christmas will be Friday 23rd December 2022, reopening on Tuesday 3rd January 2023. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Read More

Read More

2nd December 2022 - PVC Belt Bend Conveyor (Inspection Area)

PVC Belt Bend Conveyor (Inspection Area) - A brief insight into how the belt bend / curve conveyors work, via the inspection area from Amber Industries. Belt Curves, Belt Turns or Powered Belt Curves are generally considered to be a specialist type of belt conveyor and as such they are supplied by a specialist manufacturer. Gramac Quartz is the division of Amber Industries Ltd which has specialised for over 30 years in the manufacture of Belt Curves for many different combinations of load duty, arc and width formats. These time served belt curves are marketed under the Gramac Quartz brand name.

Read More

Read More

4th October 2022 - Flighted Incline Conveyor Modular Belt

Flighted Incline Conveyor Modular Belt for transporting cartons/boxes from a ground floor to a first floor. There are controls and photocells at the top and bottom for operator use. Find out more at https://youtu.be/ZFxWLXMxHBU

Read More

Read More

6th September 2022 - Amber Industries Exhibiting at Imhx 2022 6th - 8th September

Amber Industries are exhibiting at IMHX 2022 on stand 5B100 at the NEC in Birmingham from today 6th to 8th September 2022. IMHX is the largest event of its kind welcoming 16,000 professionals to see and experience the latest logistics and supply chain technology from the industry's leading names. Amber Industries will be presenting the latest innovations in conveyor systems. Register for your tickets here: https://registration.gesevent.com/survey/1z0brreqr2zzp?actioncode=WEB12

Read More

Read More

5th September 2022 - Amber Industries - 90 Degree Chain Cross Transfer Lineshaft Conveyor

Computer Generated Video Of A 90 Degree Chain Cross Transfer Lineshaft Conveyor For Transporting Cartons/Boxes Around A Production/Packing Environment. Find out more at https://youtu.be/Ef0Emqi3sa0

Read More

Read More

2nd August 2022 - Lift & Ball Table Workings

Lift & Ball Table Workings - Simple video to highlight the workings of a lift unit within a ball table. Find out more at https://youtu.be/hSEEPjWhW74

Read More

Read More

27th June 2022 - Amber Industries Exhibiting at IMHX 2022 6th - 8th September

Amber Industries will be exhibiting at IMHX 2022 on stand 5B100 at the NEC in Birmingham on 6th to 8th September 2022. IMHX is the largest event of its kind welcoming 16,000 professionals to see and experience the latest logistics and supply chain technology from the industry's leading names. Amber Industries will be presenting the latest innovations in conveyor systems. Register for your tickets here: https://registration.gesevent.com

Read More

Read More

1st June 2022 - Amber Industries - Accumulating Chain Conveyors

Accumulating Chain Conveyors - Amber Industries won a project to create a twin chain accumulating system (handling steel platens) to Include 12 turntables, complete with a goods lift for the empty returns (high level). Find out more at https://youtu.be/4eAu4eejelU

Read More

Read More

4th May 2022 - Lineshaft Skewed Powered Roller Conveyor Example Video

Lineshaft Skewed Powered Roller Conveyor Example - Amber Industries demonstrating the skewed roller effect on a lineshaft powered roller conveyor. Sending parcels/boxes/totes to one side, rather than relying on side guiding. Find out more at https://youtu.be/IM7uVH4teCE

Read More

Read More

2nd March 2022 - Surface World On From 2nd To 3rd March 2022

Amber Industries are ready for Surface World and will be exhibiting at stand H1 in Hall 11 at the NEC at Birmingham. Doors are open at 09:00 and we are looking forward to seeing many prospects and people in the industry. visiting Surface World Live 2022 is essential for all in the manufacturing sector. Come and visit us to discuss Industrial Overhead and Floor Conveyors.

Warning: Uninitialized string offset 0 in /var/www/vhosts/amber-industries.ltd.uk/httpdocs/vendor/cakephp/cakephp/src/Routing/Asset.php on line 160

Read More

Read More

16th February 2022 - Amber Industries At Surface World Exhibition 2022

The dates for Surface World Live 2022 are Wednesday 2nd and Thursday 3rd March 2022. Amber Industries will be exhibiting at stand H1. Doors open at 09:00 and we are looking forward to seeing many prospects and people in the industry. visiting Surface World Live 2022 is essential for all in the manufacturing sector. This major international exhibition in Hall 11, NEC, Birmingham, will showcase the very latest in the world of surface coatings; including surface engineering, surface technology and surface finishing, in all its many guises.

Read More

Read More

11th January 2022 - Belt Bend/Belt Curve Insights Video

A Brief Insight Into How The Belt Bend / Curve Conveyors Work, Via The Inspection Area - At one end the drive pulley is coated / lagged with a non-slip, highly wear resilient and heat resistant material which positively grips the underside of the belt. The taper of the pulley allows it to engage the belt across its full width, even at high speed, and ensures maximum power transmission from a suitably sized geared motor unit fitted to the shaft of the drive pulley. This method of driving the belt is known as 'Friction Driven'. #Amberindustries #Airports #Manufacturing #Bespoke #Beltcurves #Beltbends #Grammac #Manufacturing #conveyorsystems

Read More

Read More

2021

3rd November 2021 - Amber Industries Relocate To Larger Premises

After many years at Amber House in Oldham, Amber Industries Ltd are pleased to announce that they are moving to larger premises. The new building will represent a modern manufacturing facility and the new address is Unit 10, Southlink Business Park, Hamilton Street, Oldham, Lancashire, OL4 1DE. More information will follow on this exciting new development.

Read More

Read More

7th September 2021 - Gravity Roller Conveyor System For Transporting Stacks Of Wooden Sheet

Gravity Roller Conveyor System For Transporting Stacks Of Wooden Sheets From Processing To End Of Line. With The Inclusion Of 3 Traversing Trollies. #Amberindustries #Industry #Manufacturing #Bespoke #Wood #Manufacturing #Conveyors #Gravity #Heavyduty

Read More

Read More

2nd August 2021 - Powered Roller Conveyors

24V DC Zero Line Pressure Powered Roller Conveyors, This Video Includes An Example Of A Triple Strand Chain Transfer, And A 90 Degree Turntable.

Read More

Read More

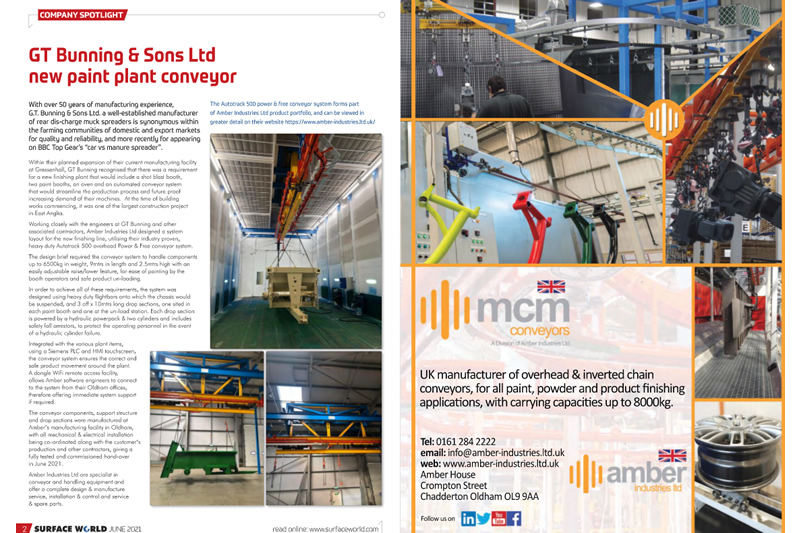

5th July 2021 - In the Spotlight - GT Bunning & Sons Ltd New Paint Plant Conveyor

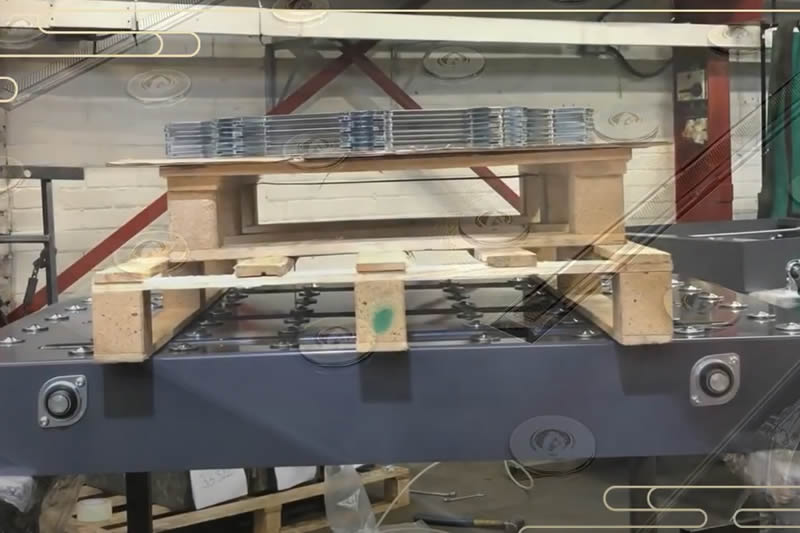

Working closely with the engineers at GT Bunning and other associated contractors, Amber Industries Ltd designed a system layout for the new finishing line, utilising their industry proven, heavy duty Autotrack 500 overhead Power & Free conveyor system. The design brief required the conveyor system to handle components up to 6500kg in weight, 9mtrs in length and 2.5mtrs high with an easily adjustable raise/lower feature, for ease of painting by the booth operators and safe product un-loading.

Read More

Read More

7th June 2021 - In the Spotlight - MCM Powertrack PT30 Overhead Conveyor Systems

Great video showing the Powertrack 30 in action conveying a well known brand of clothing. Click the link here https://fb.watch/5ZJ-BrwrpY/ to see one of our Powertrack overhead conveyors in operation.

Read More

Read More

10th May 2021 - In the Spotlight - MCM Sidetrack Overhead Monorail Conveyor Systems

A range of ‘monorail’ overhead chain conveyors with the track and chain rotated through 90° so that the C shaped hanging pendants attached to the chain project through the side slot in the track.

Read More

Read More

2nd April 2021 - The New Year Sees a New Type of Slat-Conveyor

It is a common misconception that plastic is a poor choice for high temperature and impact applications, with fear of it melting or fracturing. Our Plastic Modular Belt conveyors, Utilise Specifically manufactured Plastics to offer outstanding performance for almost every application. Find out more at www.amber-industries.ltd.uk/steel-plastic-wire-mesh-conveyors

Read More

Read More

5th March 2021 - Record Production Of Belt Bend Curve Announced

The last 12 months have presented challenges for all of us as individuals, families, organisations and businesses. Despite the challenges of the global pandemic Amber Industries is pleased to announce that we had a record year for the production of our specialised belt bend product range. Our Gramac Quartz powered belt curves are manufactured in the UK for both home and export trade allowing for many different combinations of load duty, arc and width formats. These time served belt curves are marketed under the Gramac Quartz brand name.

Read More

Read More

2nd February 2021 - 360 Degree Rotation Product Platform

Amber Industries recently designed, manufactured and tested a 360 Degree Rotation Product Platform which is now ready for despatch. In this application our customer needed a solution that offers ease of 360 degree rotation for assembling products, whilst intermittently needing to hold the product static for installation of components and testing. Get in touch with your requirements and see where Amber Industries can help.

Read More

Read More

5th January 2021 - Operational Update for Coronavirus COVID 19 & Amber Industries

Amber Industries is a primary UK designer, manufacturer & supplier of conveyor equipment and systems with over 40 years experience in the automated mechanical handling and conveyor industry. As such, we will continue to support our industry in any way we can. We are open for business across all aspects of our products and services for our customers. Wherever possible employees are working remotely from home. Production staff, site staff and contractors are all operating within hands, face and space guidelines allowing us to process enquiries and fulfil orders. We are available to deal with any requests so please contact us for more information.

Read More

Read More

2020

2nd December 2020 - Seasons Greetings From Amber Industries

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December into 2021 and will be operational offering industrial conveyor systems, maintenance and spare parts. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Read More

Read More

5th November 2020 - Honeycomb Conveyor Belts for Many Applications

A Honeycomb conveyor belt has many and varied uses including some of these typical applications; Transport, Cooking, Heating, Drying, Cooling, Drainage, Freezing, Baking, Washing, Breading, Packaging, Sorting, Recycling, Elevating, Loading, Canning, Painting and Assembly.

Read More

Read More

1st October 2020 - Composite Manufacturing Overhead Conveyor Design To Installation

From design to installation, Amber Industries completed a AT100 power and free system for a major composites supplier. The MCM Autotrack range of power & free conveyors (AT50, AT100, AT500M and AT600) are specifically designed with the flexibility to allow product loads to be directed along different routes within an overall conveyor system. This means that each specific product type can be identified (electronically or with mechanical flags) and automatically routed to specific destinations, e.g. process plant lines, assembly lines, storage zones, inspection and unload stations etc., in any desired sequence.

Read More

Read More

3rd September 2020 - MCM Autotrack Power & Free Overhead Conveyor System Completed

Our power & free conveyorised have great flexibility and durability, allowing you to vary the dwell time in the oven to ensure sufficient and uniform heat transfer into the product. This recent installation was for a powder coating plant. The system uses two tracks, one above the other. Power & Free allows us more flexibility with your system. The top or “power” track, contains a drive chain. This chain enables the movement of product flight bars. These are located within the lower, “Free” conveyor track.

Read More

Read More

3rd August 2020 - Drum Transferring System, incorporating Lineshaft and Powered Roller Conveyor

Lineshaft roller conveyors are powered by a shaft running longitudinally beneath the rollers to which are attached a series of spools. Polyurethane O-rings run from each spool around a groove in the rollers, thus as the shaft is rotated by an electric motor the rollers also rotate in turn pushing the product along the conveyor.

Read More

Read More

2nd July 2020 - Bespoke Belt Bends Improving the Manufacturing Flow

Amber Industries, supporting key suppliers of key products with bespoke belt bend, improving the manufacturing flow. Doing our bit to keep the UK moving. The Gramac Quartz Belt Curves robust and patented design consists of a strong and rigid frame fabricated from steel section and plate rolled and formed to give the desired angle and radius. A stiffened smooth steel slide bed is mounted within the frame to support the belt and over which the belt slides.

Read More

Read More

4th June 2020 - Revised Intralogistex Dates Announced for 2020

Amber Industries will be in full attendance at IntralogisteX 2020 promoting our industrial conveyors at Stand 1130, on 9th - 30th September 2020 at the Ricoh Arena, Coventry UK. Amber Industries Limited will be demonstrating our package/tote/carton handling conveyor modules, operating as a simple working system. Amber’s experience and creative attitude have made them a successful UK 'medium' sized system integrator who specialise in the design, manufacture and installation of mechanical handling & conveyor solutions.

Read More

Read More

11th May 2020 - Revised Surface World Dates Announced for 2021

The new dates for Surface World Live are 24th and 25th February 2021. The organisers of Surface World Live 2020 came to the decision that in light of the current Covid-19 situation increasing in the UK and the latest update from WHO, PHE and the British Government that it was safer to postpone the show to early next year. The well-being and safety of all Exhibitors, Visitors and Staff had to be the top priority. Thank you for your understanding while all the necessary arrangements were being facilitated for the events postponement.

Read More

Read More

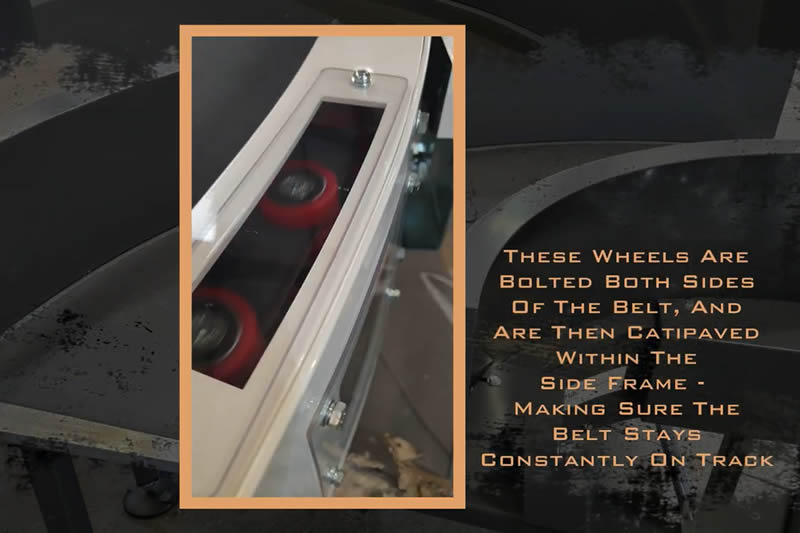

4th April 2020 - Introducing the Maintenance Window on Amber Belt Curves

Introducing the new maintenance window on the Amber TSTR150 curves. Maintenance and inspection is a major component for optimum performance across all belt bend applications. This is especially important for Intralogistex installations that are in continued usage 24/7.

Read More

Read More

19th February 2020 - Visit Us at Intralogistex 2020 @ the Ricoh Arena

Amber Industries will be in full attendance at IntralogisteX 2020 promoting our industrial conveyors at Stand 1130, The Ricoh Arena, Coventry on Tuesday 31st March & Wednesday 1st April 2020. Amber Industries Limited will be demonstrating our package/tote/carton handling conveyor modules, operating as a simple working system. Amber’s experience and creative attitude have made them a successful UK 'medium' sized system integrator who specialise in the design, manufacture and installation of mechanical handling & conveyor solutions.

Read More

Read More

23rd January 2020 - Visit Us at Surface World 2020 @ the NEC

Amber Industries will be in full attendance at Surface World 2020 promoting our MCM Conveyors division at Stand H1, Hall 9, NEC, Birmingham on Wednesday 18th & Thursday 19th March 2020. Come and visit our booth to discuss your project and how we can help you through the complete process from design, manufacture, installation and maintenance. We look forward to seeing you.

Read More

Read More

2019

3rd December 2019 - Season's Greetings From Amber Industries

We would like to take this opportunity to say thank you to everyone involved with our company including customers, staff, suppliers and partners for your support during the year. We are looking forward to 2020 and working with all of you again next year. Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. Our last working day before Christmas will be Tuesday 24th December, which makes our last day for despatch of stock items Friday 20th. We are open on Thursday 2nd January 2020.

Read More

Read More

7th November 2019 - Multi-million Pound Overhead Conveyor System Nearing Completion

Amber Industries are nearing completion of an "AT100 power and free overhead conveyor system", which is part of a multi-million euro expansion program by a key international automotive components supplier. The success of a Power & Free conveyor system lies in it’s flexibility of operation, allowing the flow of product to be controlled with the correct sequencing taking place to suit a customers individual and specific requirements and working environment.

Read More

Read More

9th October 2019 - Inclined Belt Conveyors Order Fulfilled

We have recently undertaken a large contract for the supply of a belt conveyor system within a FMCG (Fast Moving Consumer Goods) facility. The order was placed specifically to coincide with the Christmas sales activity increase for our customer. The image shows us having undertaken the finishing touches to one of our inclined belt conveyors, helping presents flow for the fast approaching Christmas period.

Read More

Read More

3rd September 2019 - Amber Industries Exhibiting at IMHX 2019 24 -27 September

Amber Industries will be exhibiting at IMHX 2019 on stand 19J22 at the NEC in Birmingham on 24th to 27th September 2019. IMHX is the largest event of its kind welcoming 16,000 professionals to see and experience the latest logistics and supply chain technology from the industry's leading names. Amber Industries will be presenting the latest innovations in conveyor systems.

Read More

Read More

6th August 2019 - Overhead Conveyor Chain for Export

We have recently completed a very large order for overhead conveyor spares being shipped to a European installation. Several tonnes of overhead conveyor spares where supplied for a complete overhaul of a heavy duty system. Even the most reliable of conveyor systems require worn parts to be replaced from time to time. Amber Industries offers a full range of spare parts for all the conveyor equipment it supplies, i.e. overhead chain conveyors, powered roller conveyors and belt conveyors.

Read More

Read More

2nd July 2019 - Powered Roller Conveyor System Installation Completed

Products can be accumulated on lineshaft conveyors with a queue of items can be allowed to form to create an in-line buffer store without stopping the upstream movement of products on the conveyor system. This is possible because a property of the lineshaft drive mechanism design is that it only generates low levels of line pressure. This is the amount of force acting between touching products in the queue. When products are stopped on the conveyor by a mechanical stop, the friction between the product and the rollers beneath then causes the rollers to stop rotating and the corresponding O-rings to slip on their spools, without affecting any other rollers elsewhere on the conveyor.

Read More

Read More

6th June 2019 - Autotrack 100 Power & Free Overhead Conveyor Project

Autotrack 100 power & free overhead conveyor project, designed, manufactured in the UK, installed including controls system and support structure by Amber Industries Ltd. We hope you enjoy the video clip of one of our overhead conveyors in action for a recent installation.

2nd May 2019 - Belt Curve Contract Fulfilled

Belt Curves have a proven track record of longevity and reliable operation around the globe in a variety of environments and industries including: post and parcel handling, airport baggage handling, warehouse and distribution centres, refrigerated storage units, print and packaging, laundries, cement, plaster and building materials, horticultural and garden fertilizer and compost products and many other general manufacturing and industrial applications where changes in direction of conveyed objects are required.

Read More

Read More

2nd April 2019 - Mesh Belt Conveyors in the Spotlight

We have recently designed, manufactured and installed a high temperature mesh belt floor conveyor into a modern manufacturing facility. This type of floor conveyor is ideal for usage in drying ovens and tunnel ovens where this is a curing, annealing, hardening, sintering & brazing application where consistent speed and controlled environment temperatures are required.

Read More

Read More

6th February 2019 - 180 Degree Belt Curves From Amber Industries

We are specialists in the design, manufacture and installation of 180 degree belt curves/belt bends for integration with conveyors, belt conveyors, warehouse logistics, box handling, baggage handling and airport systems. In the image we have a recently manufactured 180 degree belt curve ready to be installed on one of our customer projects.

Read More

Read More

9th January 2019 - Lift Up Gates in the Spotlight

Amber Industries offer significant expertise in the complete box, package and parcel handling system. We have a number of options for clean areas handling where complex movement paths are required. The Amber Lift Up gate presented in this image is a heavy duty element in a roller conveyor system or a belt conveyor system.

Read More

Read More

2018

4th December 2018 - Season's Greetings From Amber Industries

We would like to take this opportunity to say a thank you to everyone involved with our company including customers, staff, suppliers and partners for your support during the year. We are looking forward to 2019 and working with all of you again next year. Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. Our last working day before Christmas will be Friday 21st December, which makes our last day for despatch of stock items Thursday 20th. We are open on Wednesday 2nd January. We would like to wish our customers & suppliers the best wishes for the festive season.

Read More

Read More

1st November 2018 - Amber Industries Become Members of AMHSA

AMHSA is the voice of the automated materials handling industry. The Association is committed to promoting excellence in the automated material handling industry in terms of solutions, after sales support, reliability and safety. AMHSA promotes the interests of its members, defines and upholds best practice in the industry and aims to be a leading example of excellence. Amber Industries see benefits of membership of AMHSA providing assistance in improving business operations and management practices including the development of collaborative practices.

Read More

Read More

2nd October 2018 - Thank You For Visiting Surface World Live 2018

We would like to thank all who attended Surface World 2018 at the NEC which was held recently. The show was a big success for Amber Industries and its MCM Conveyor division. Our stand was a hive of activity throughout both days with lots of interest in our MM Conveyor range especially our Autotrack range of power & free overhead chain conveyor systems which are suitable for handling light, medium and heavy products in many different formats.

Read More

Read More

3rd September 2018 - Visit Us At Surface World 2018 @ The NEC

Amber Industries will be in full attendance at Surface World 2018 promoting our MCM Conveyors division at Stand A1, Hall 11, NEC, Birmingham on Wednesday 19th & Thursday 20th September 2018. Come and visit our booth to discuss your project and how we can help you through the complete process from design, manufacture, installation and maintenance. We look forward to seeing you.

Read More

Read More

8th August 2018 - MCM Autotrack Installation At SEW Eurodrive Revisited

The MCM Autotrack range of power & free overhead chain conveyor systems are suitable for handling light, medium and heavy products in many different formats. The quality of their design and manufacture and their durability has been proven numerous times in many demanding industrial applications. Their reliability over many years of continuous operation is unsurpassed makings them a valuable long term asset in our client’s production facilities.

Read More

Read More

1st June 2018 - Complete Turnkey Floor Conveyor System Project

Amber industries recently designed, manufactured and installed a complete bespoke floor conveyor system incorporating ZLP roller conveyors, PLC controls system, product display monitors, barcode scanning, operator interface for product identification in assembly zone. You will see from the image that this is a multi-function floor conveyor installation to meet the requirements of our UK based customer.

Read More

Read More

1st May 2018 - Switch & Echelon Accumulation System Commissioning

Commissioning in progress with a switch and echelon accumulation Autotrack 100 power & free overhead conveyor project, designed, manufactured, installed including controls system and steelwork by Amber Industries Ltd UK. The MCM Autotrack range of power & free conveyors (AT50, AT100, AT500M and AT600) are specifically designed with the flexibility to allow product loads to be directed along different routes within an overall conveyor system. This means that each specific product type can be identified (electronically or with mechanical flags) and automatically routed to specific destinations, e.g. process plant lines, assembly lines, storage zones, inspection and unload stations etc., in any desired sequence.

23rd April 2018 - Floor Conveyor System Installation

Installation in progress for an Amber floor conveyor system incorporating ZLP roller conveyors, PLC controls system, 32" product display monitors, barcode scanning, operator interface for product identification in assembly zone. Automated floor conveyor systems are extensively used in warehouses, distribution centres, parcel sorting depots, and all kinds of factory environments; anywhere where unit loads need to be moved.

Read More

Read More

10th March 2018 - Tecomet Choose Amber For A Vertical Lift With Integrated Transfer Unit

Tecomet is the world’s largest contract manufacturer of medical implants and devices, they specialise in manufacturing and engineering solutions in Forging, Casting and machining of medical as well as aerospace & defence products. The company has a global presence with over 16 sites across 3 continents. The Sheffield site is the largest outside the United States. The Casting Department at Tecomet, Sheffield recognized a need to improve their existing processes and efficiencies to accommodate their current and future production demands. A key improvement area identified was the offloading of the final castings.

Read More

Read More

2nd February 2018 - Curved Plastic Modular Belt Conveyor System

Amber Conveyors have recently manufactured a Plastic Modular Belt Conveyor which is currently undertaking testing and trials prior to system integration in Poland. The actual belt allows for cornering using slides and guides under the plastic modular. Modular plastic belt conveyors are often used in the food and pharmaceutical industries because they can be washed down, however they are extremely versatile and can be suitable for a great many application. Plastic modular belts are made from small plastic sections which are hinged together with linking pins to form a belt, typically with a ‘chain mail’ like appearance.

Read More

Read More

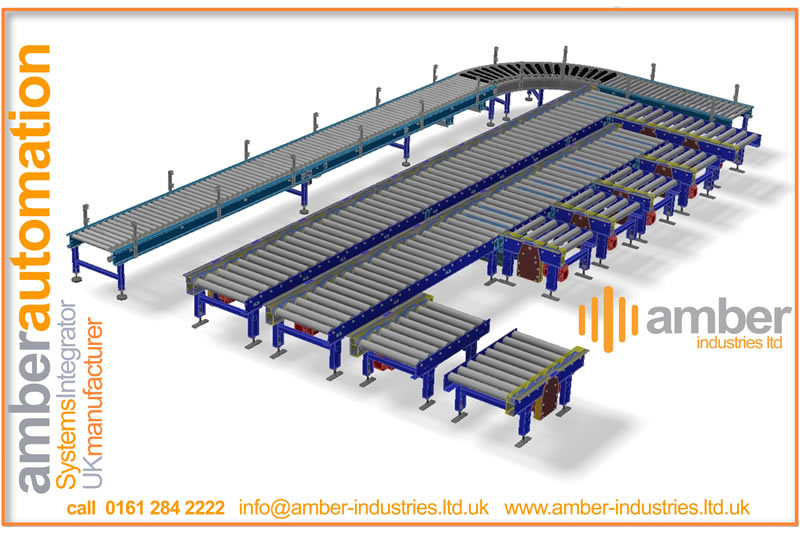

15th January 2018 - Tailored Floor Conveyor Systems From Amber Industries

Amber Industries have all of the components for your world class floor conveyor system logistics requirements. We are in a position to design, manufacture and install your system including project management 3D design, layouts and complete full system integration.

Read More

Read More

2017

1st December 2017 - Season's Greetings From Amber Industries

We would like to take this opportunity to say a thank you to everyone involved with our company including customers, staff, suppliers and partners for your support during the year. We are looking forward to 2018 and working with all of you again next year. Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year.

Read More

Read More

3rd October 2017 - Mobile Conveyors Curved To Suit Your Specification

Amber Industries are market leaders in the manufacture supply and installation of mobile conveyors, being gravity or powered operated, curved or straight alignment, belt or rollers to suit your specification. The example below presents one of our latest gravity, curved roller mobile conveyors which is ready to use as part of a complete system. The image also offers an insight into our quality of build which allows for many years of heavy duty usage.

Read More

Read More

1st September 2017 - Re-link Your Existing Overhead Conveyor With New Chain

Amber Industries are experts at overhead conveyors. We are number 1 in Google for the search term which is testimony to our expertise. Even the most reliable of conveyor systems require worn parts to be replaced from time to time. Amber Industries offers a full range of spare parts for all the conveyor equipment it supplies, i.e. overhead chain conveyors, powered roller conveyors and belt conveyors.

Read More

Read More

1st August 2017 - Two Tier Lineshaft & Gravity Roller Conveyors Installed

Amber Industries have recently undertaken a Two Tier Lineshaft & Gravity Roller Conveyors complete with c/w controls. Ideal for picking, production and packaging lines, these fixed conveyors are designed to quietly carry regular shaped unit loads up to 50Kg/metre and to require minimal maintenance.

Read More

Read More

6th July 2017 - E-commerce Box Handling Systems Installed

Amber Industries have undertaken a number of Floor Conveyor systems designed to handle e-commerce boxed items off all weights and sizes. Belt conveyors can be supplied as units or as part of a complement amber automation system with full controls and management systems.

Read More

Read More

2nd May 2017 - Introducing Live Chat For Extra Communication

As part of our updated customer services team developments, we have introduced a live chat system to our UK based website. This is allowing our website visitors to have an additional direct communication method with instant responses during normal office hours. We are also trialling this in our German and Italian websites with a view to ensure that we can answer all questions and enquiries in an optimum manner.

Read More

Read More

3rd April 2017 - Introducing Intralogistics Belt Curves - The TS-TR100

Gramac Quartz Belt Curves: designed to smoothly change the travel direction of products within high speed handling systems. Gramac Quartz is the division of Amber Industries Ltd which has specialised for over 30 years in the manufacture of Belt Curves for many different applications and combinations of load duty, arc and width formats. Its TS-TR100 range of belt curves have been purposely designed for incorporation into the most demanding a handling environments.

Read More

Read More

27th March 2017 - Amber Industries - Surface World

7th February 2017 - New Amber Industries Website Launched In German

Amber Industries are pleased to announce the launch of an German language website specifically aimed at the largest economy in Europe after the UK. You will find our new website on www.amberindustries.de. The new site has extensive content including full product range details technical resources, a dedicated maintenance section including products, conveyor options and our research and development activities.

Read More

Read More

11th January 2017 - Amber Industries To Exhibit At Surface World 22nd & 23rd March 2017 Birmingham NEC

Amber Industries will be exhibiting at Surface World 2017 from March 22nd to 23rd at the NEC in Birmingham, Hall number 7, Booth number G1. The exhibition is the UK’s only international event dedicated to the surface treatment, product finishing and coatings industry. It provides a major showcase for the very latest technology and developments in this important and expanding area.

Read More

Read More

2016

15th December 2016 - Season’s Greetings From Amber Industries

We would like to take this opportunity to say a thank you to all of our staff, stakeholders, suppliers, partners and customers for your support during 2016. We are looking forward to 2017 and working with all of you next year. Season’s greetings from all of us and we wish you a happy Christmas and a prosperous New Year.

Read More

Read More