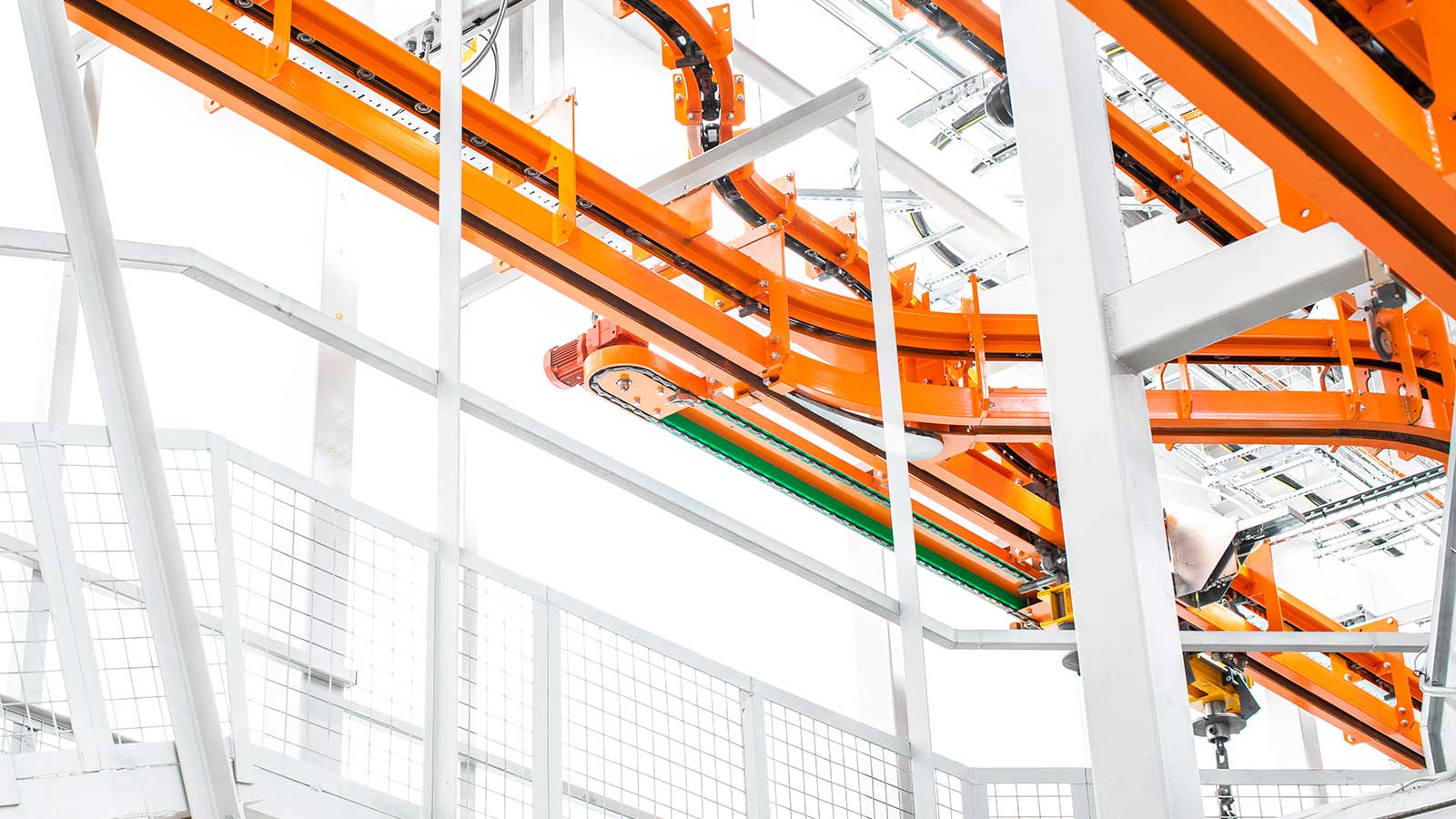

MCM Autotrack – Power & Free Conveyor Systems

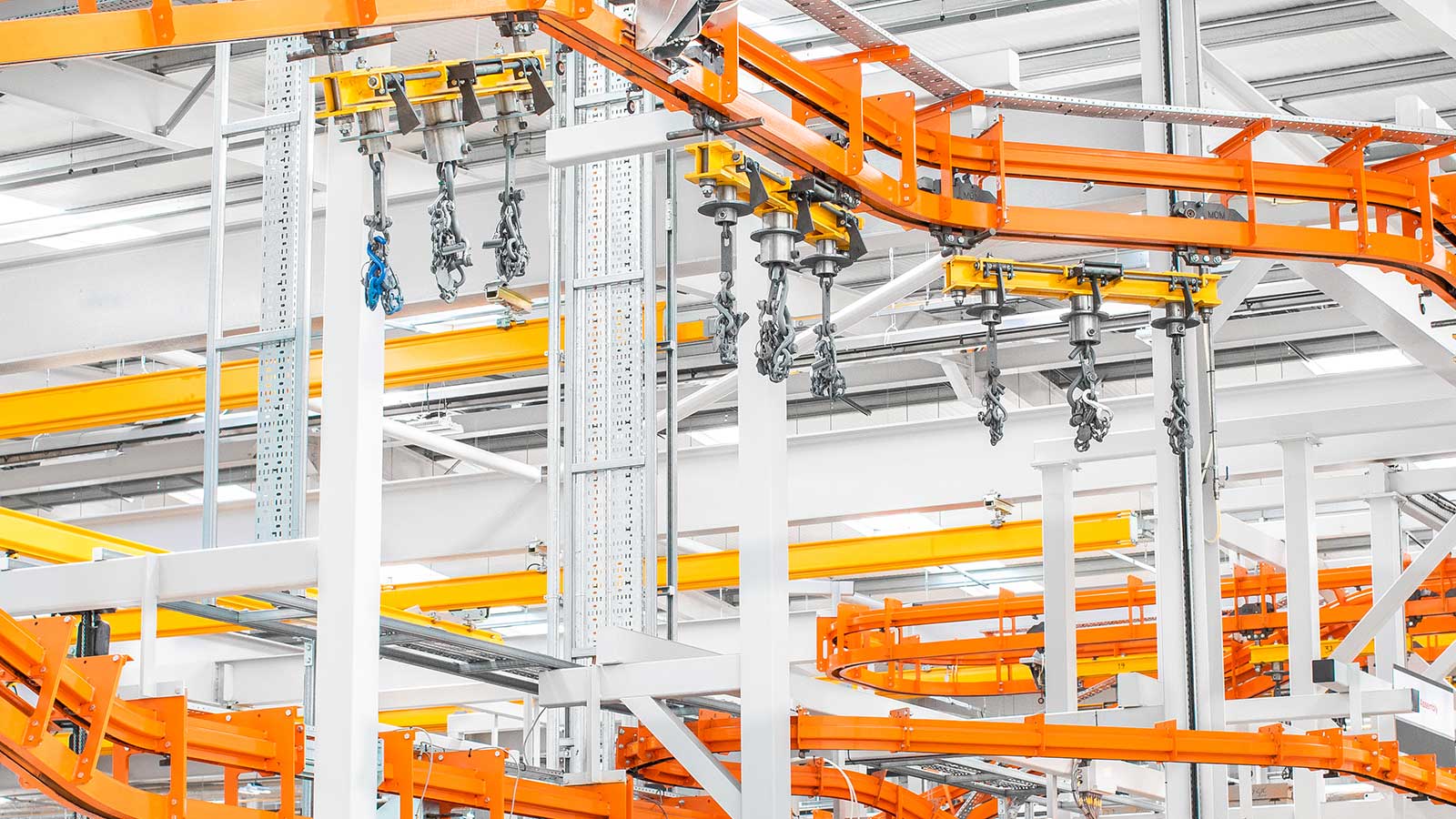

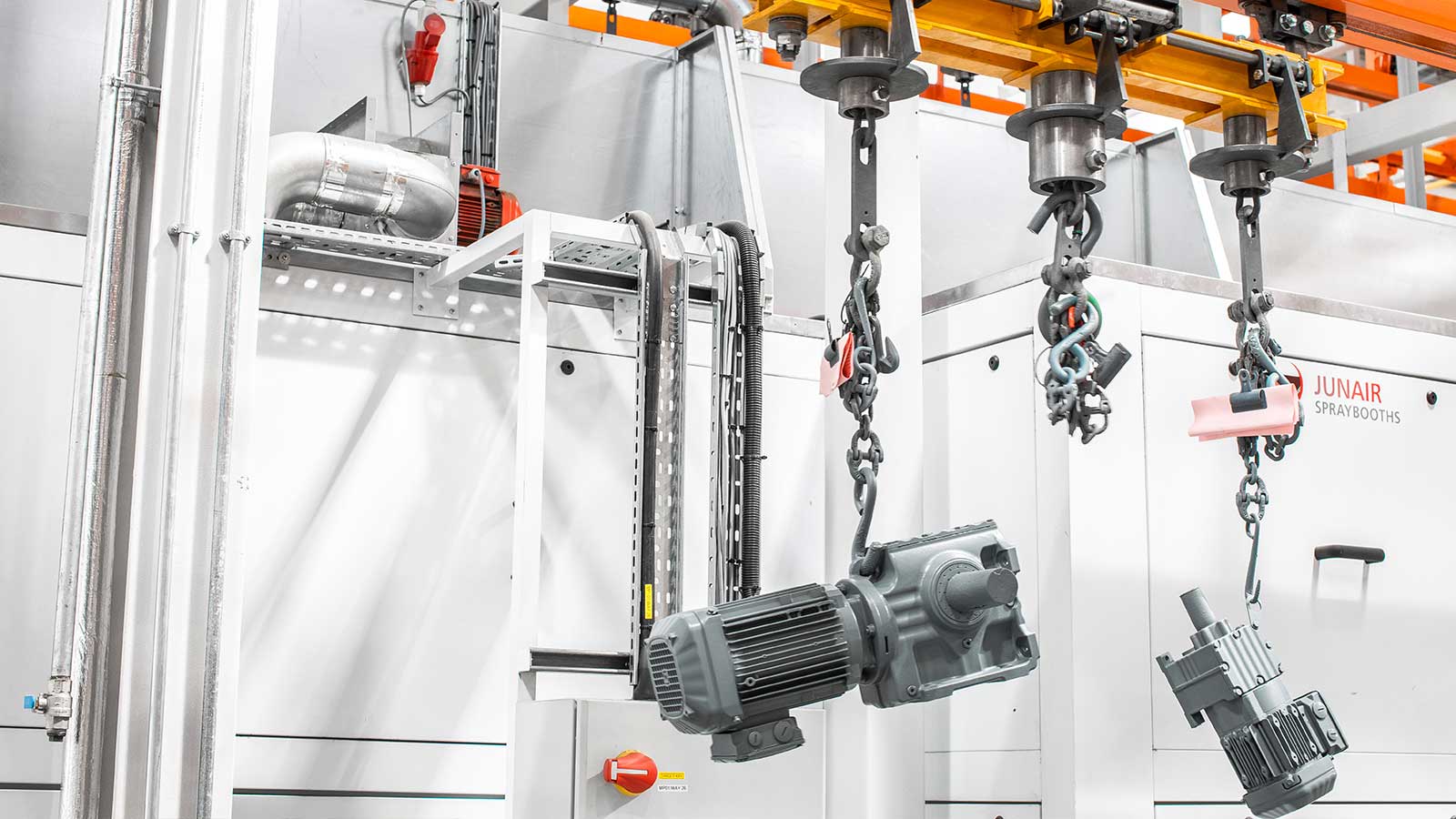

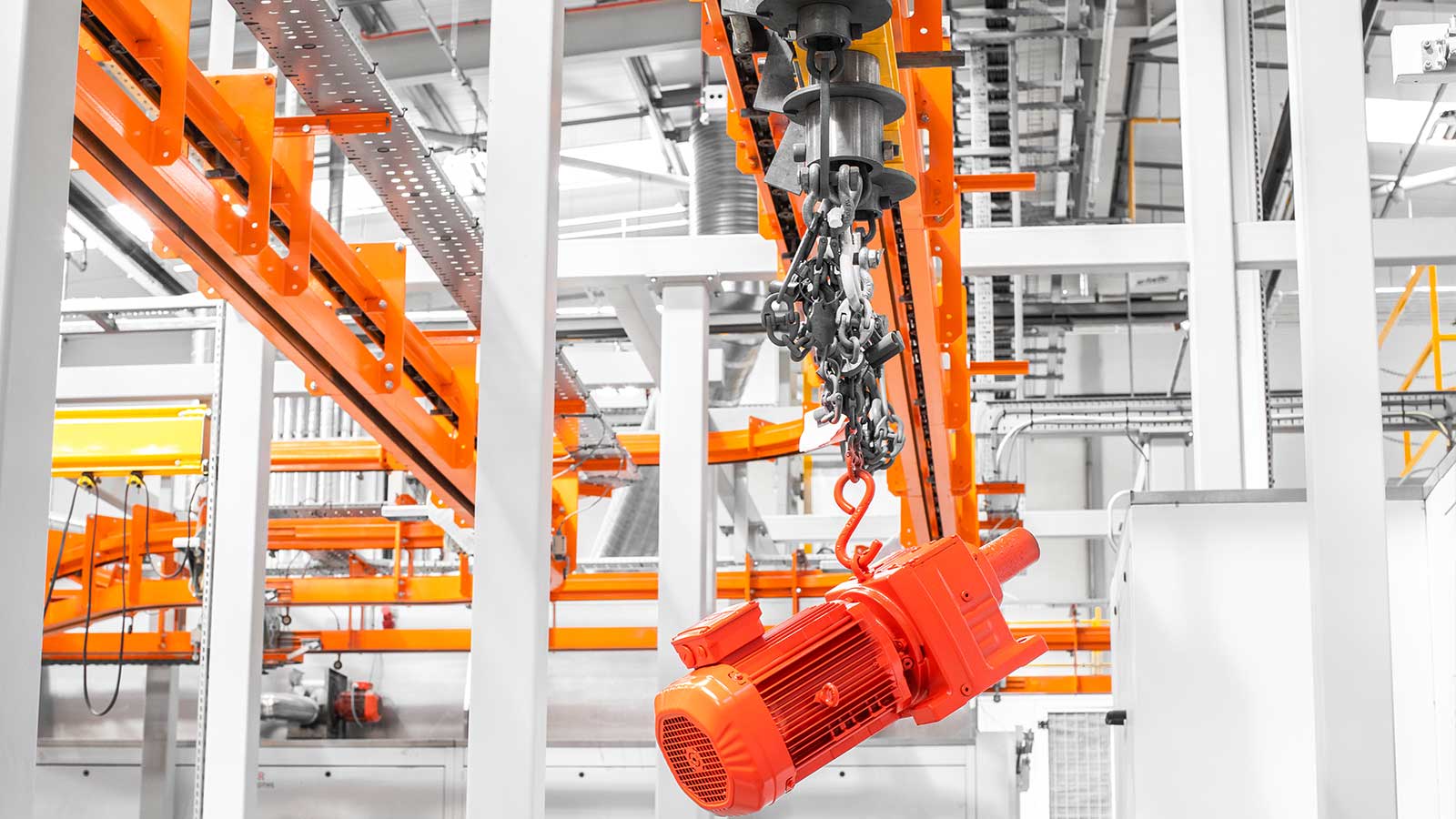

A range of ‘power & free’ overhead chain conveyors designed with the flexibility to allow product to be directed along different routes within the same system depending upon the sequence of processes to be applied. The two coextensive tracks (chain and trolley) of the MCM Autotrack conveyor system enable the formation of buffer storage and accumulation zones, automatic route selection and speed changes. This means that any product type can be identified (electronically or with mechanical flags) and automatically sent to specific destinations e.g. process plant lines, assembly lines, inspection stations and unload zones etc. in any desired sequence.

Product loads can be stopped at almost any position within a ‘power & free’ system to allow various manufacturing operations to be performed. Product loads can also be stored within a buffer storage area enabling production imbalances and the impact of shift changes to be smoothed out. Speed changes through designated conveyor system zones can be incorporated to match the requirements of an in-line processes. Powered ‘drop sections’ can be built into a ‘power and free’ conveyor systems to raise or lower product loads to facilitate certain operations or loading and unloading larger products.

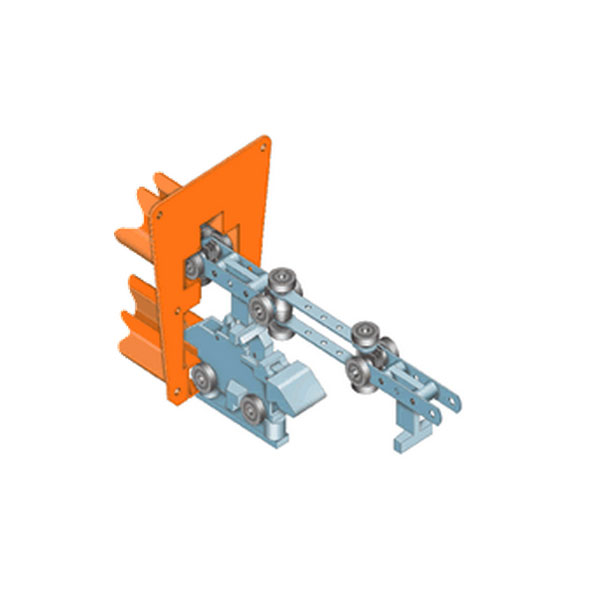

The MCM Autotrack range of ‘power & free’ conveyors include a system (AT50, AT100, AT500M, & AT600) suitable for handling light, medium and heavy products of many different types. For instance AT500 systems have been used for carrying 6000Kg + trailer chassis through surface coating plants and assembly lines.

Autotrack 'Power & Free' Overhead Chain Conveyors

| Conveyor Model | Load Capacity | Data Sheets |

|---|---|---|

| Autotrack 50 | 50Kg per trolley | |

| Autotrack 100 | 100Kg per trolley | |

| Autotrack 500 | 500Kg per trolley | |

| Autotrack 500S* | 500Kg per trolley |

* Higher chain pull characteristics.