Belt Bend/Belt Curve Insights Video

11

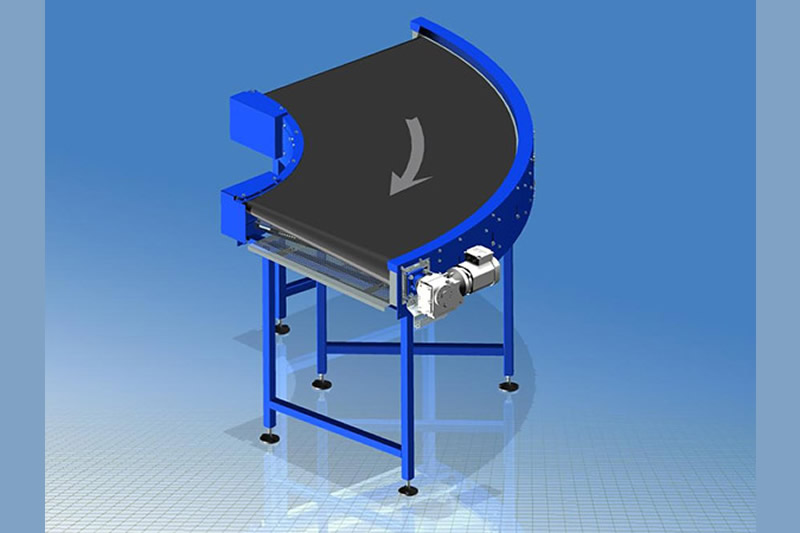

A Brief Insight Into How The Belt Bend / Curve Conveyors Work, Via The Inspection Area - At one end the drive pulley is coated / lagged with a non-slip, highly wear resilient and heat resistant material which positively grips the underside of the belt. The taper of the pulley allows it to engage the belt across its full width, even at high speed, and ensures maximum power transmission from a suitably sized geared motor unit fitted to the shaft of the drive pulley. This method of driving the belt is known as 'Friction Driven'. #Amberindustries #Airports #Manufacturing #Bespoke #Beltcurves #Beltbends #Grammac #Manufacturing #conveyorsystems

All Gramac Quartz Belt Curves are supplied with safety guards fitted to eliminate trap points and prevent inadvertent access to moving parts such as the roller guide bearings. These guards are designed to be lightweight for easy removal for maintenance purposes. Underside guarding is provided as standard.

Other Articles

Amber Industries Exhibiting At Paint Expo 2026

18

Technical Data For Overhead Chain Conveyors Published

20

Season's Greetings From Amber Industries

15

Control Systems For Overhead Conveyor Automation

4

MCM Powertrack Range From Amber Industries

4

MCM Freetrack Conveyor Systems In Focus

13

MCM Dualtrack Inverted Conveyor System

1

Laundry Conveyors by Amber Industries

13

MCM Powertrack Overhead Monorail Conveyor Systems

11

Belt Curves for Airport Baggage Handling Systems

2