In the Spotlight - GT Bunning & Sons Ltd New Paint Plant Conveyor

5

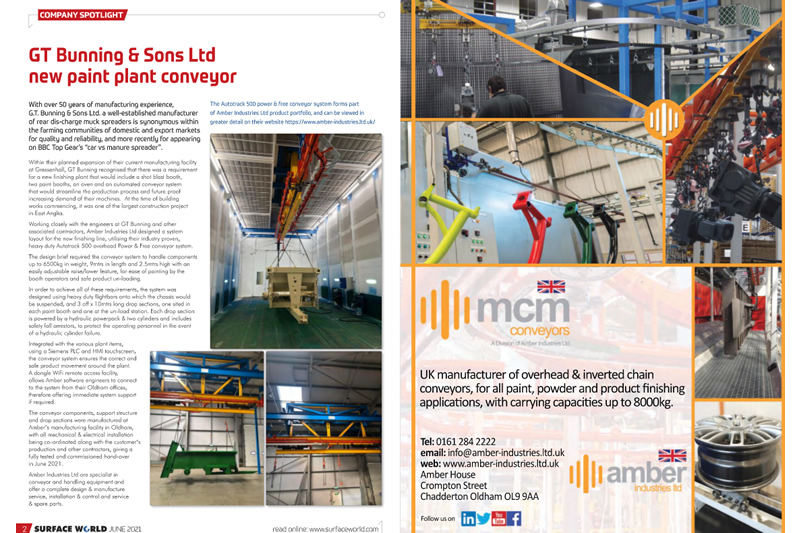

Working closely with the engineers at GT Bunning and other associated contractors, Amber Industries Ltd designed a system layout for the new finishing line, utilising their industry proven, heavy duty Autotrack 500 overhead Power & Free conveyor system. The design brief required the conveyor system to handle components up to 6500kg in weight, 9mtrs in length and 2.5mtrs high with an easily adjustable raise/lower feature, for ease of painting by the booth operators and safe product un-loading.

In order to achieve all of these requirements, the system was designed using heavy duty flightbars onto which the chassis would be suspended, and 3 off x 10mtrs long drop sections, one sited in each paint booth and one at the un-load station. Each drop section is powered by a hydraulic powerpack & two cylinders and includes safety fall arrestors, to protect the operating personnel in the event of a hydraulic cylinder failure.

Integrated with the various plant items, using a Siemens PLC and HMI touchscreen, the conveyor system ensures the correct and safe product movement around the plant. A dongle WiFi remote access facility, allows Amber software engineers to connect to the system from their Oldham offices, therefore offering immediate system support if required.

The conveyor components, support structure and drop sections were manufactured at Amber’s manufacturing facility in Oldham, with all mechanical & electrical installation being coordinated along with the customer’s production and other contractors, giving a fully tested and commissioned hand-over in June 2021. Amber Industries Ltd are specialists in conveyor and handling equipment and offer a complete design & manufacture service, installation & control and service & spare parts.

Other Articles

Amber Industries Exhibiting At Paint Expo 2026

18

Technical Data For Overhead Chain Conveyors Published

20

Season's Greetings From Amber Industries

15

Control Systems For Overhead Conveyor Automation

4

MCM Powertrack Range From Amber Industries

4

MCM Freetrack Conveyor Systems In Focus

13

MCM Dualtrack Inverted Conveyor System

1

Laundry Conveyors by Amber Industries

13

MCM Powertrack Overhead Monorail Conveyor Systems

11

Belt Curves for Airport Baggage Handling Systems

2