MCM Powertrack - Overhead Monorail Conveyor Systems

A range of monorail overhead chain conveyors suitable for handling a wide variety of products in many industry sectors, e.g. automotive, surface finishing, meat processing, general manufacturing. MCM Powertrack overhead conveyors come in two types: ‘enclosed chain’ for loads up to 100Kg, where the powered chain runs in a pressed steel enclosed track section and ‘open chain’ for heavier loads up to 500Kg where the chain is slung under a rolled steel I-section using trolleys.

MCM Powertrack Overhead Conveyors

MCM Powertrack Overhead Conveyors

MCM Powertrack Overhead Conveyors

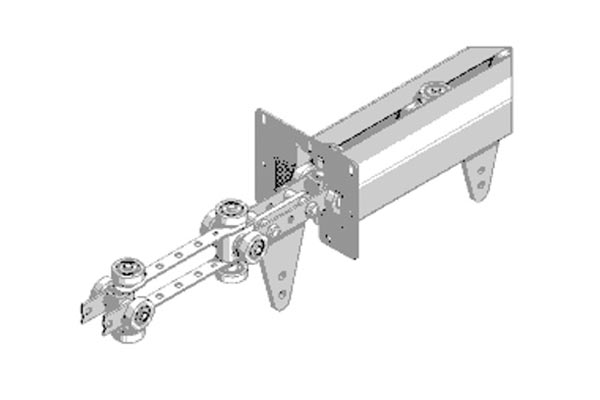

Powertrack Enclosed Chain Conveyor Systems

These systems are comprised of a bi-planar chain powered by a drive unit and running in an enclosed steel track which can either be rectangular in cross section or a cruciform shape where a higher load carrying capacity is required.

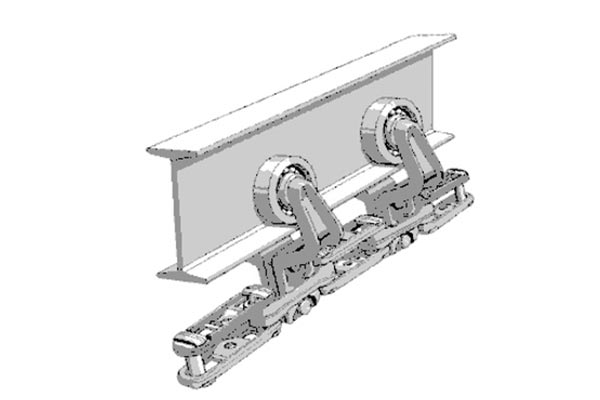

Powertrack Open Chain Conveyor Systems

The open chain Powertrack range, PT200 and PT500 utilise an I -beam track section from which a drop forged chain is underslung by means of trolleys with their wheels running on the lower flange of the I-beam.