Amber Industries is experienced in engineering and delivering a full range of conveyor systems for moving linen around laundries. Examples include:

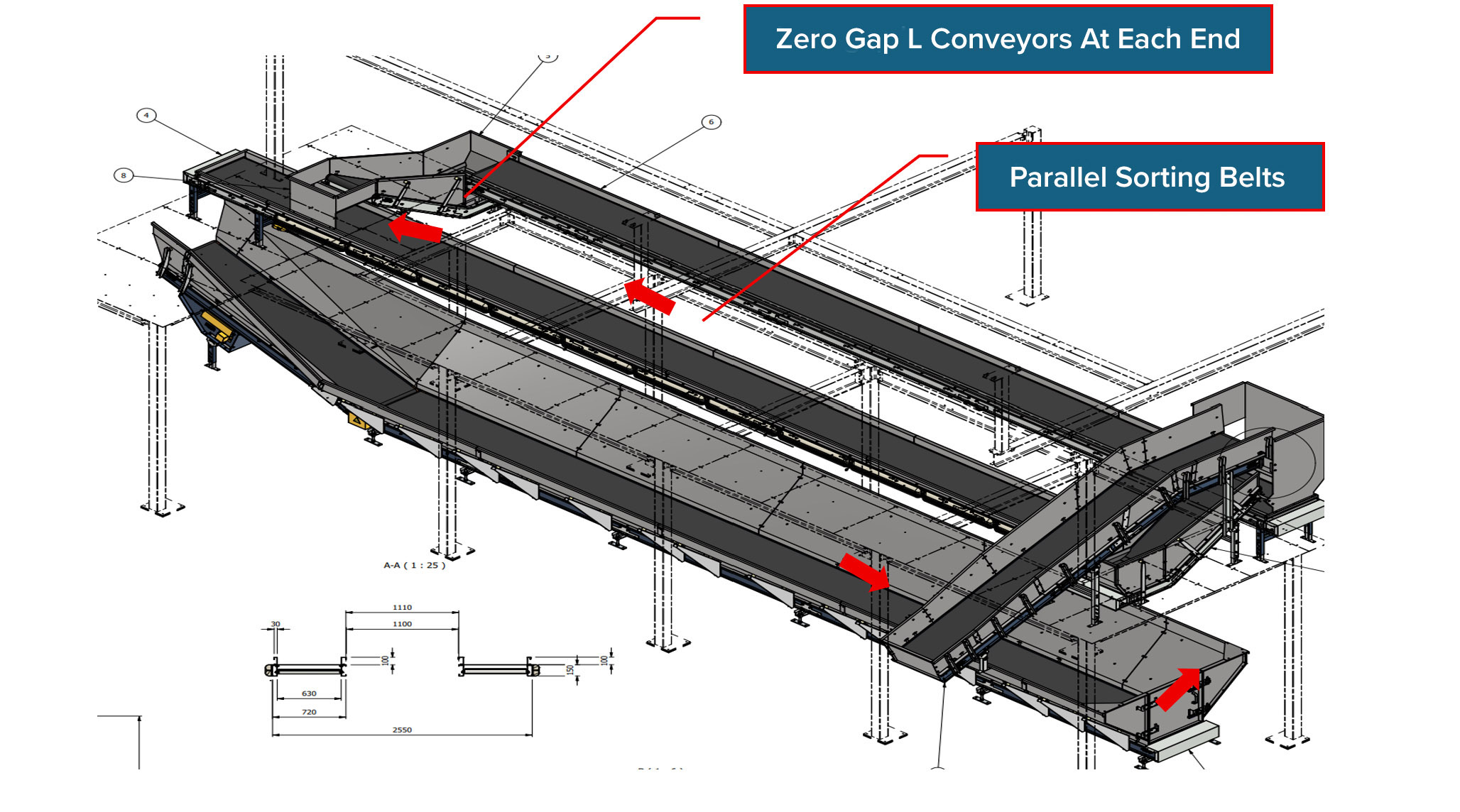

Recirculating linen on sorting platforms without jams

Parallel sorting conveyors requiring special treatment at the cross transfer sections at each end to allow loose linen to be recirculated efficiently without taking a lot of space. Special attention is paid to detailing to avoid frequent jams.

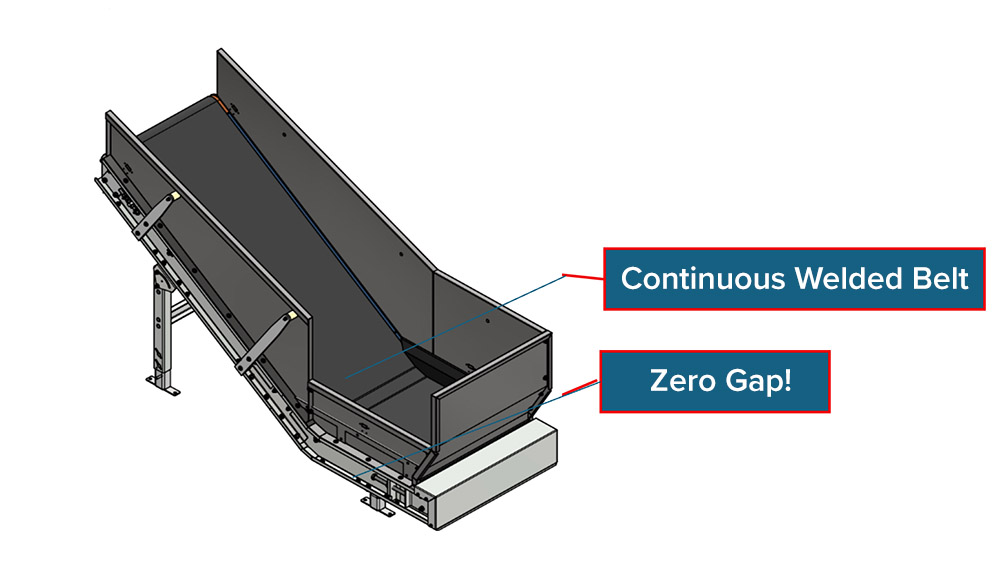

'Zero Gap' L Typical Transfer Conveyors

'Zero gap' L conveyors allow linen to be reliably transferred between parallel sorting belts by eliminating the gap traditionally found between the belts of the horizontal and inclined sections of conveyor. The “zero gap” conveyors make the belts safer (no finger traps at the base of the incline) and much more efficient (no snagging or jamming of linen tags because of elimination of any gaps between rollers).

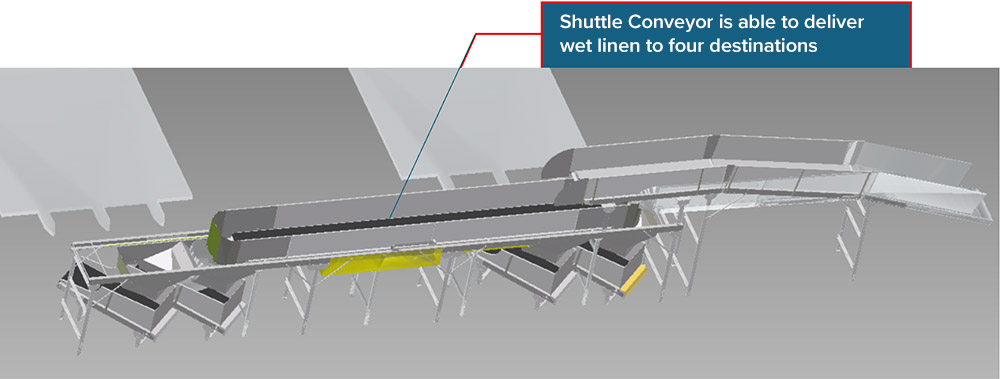

Delivering linen to multiple ironers without taking up lots of floor space

The floor space required to feed loads of 80 kg wet linen to an Ironer line can be reduced by mounting the conveyors overhead. The shuttle conveyor from Amber Industries can be used to transfer the wet linen to up to four individual ironers. The shuttle conveyor is ceiling mounted and drops linen to one of four buffer conveyors from where the operators pick individual items.

The shuttle conveyor is sized to take a full 80 Kg load of linen direct from the cake breaker Its benefits over traditional methods, include, helping to break up the load by spreading it over the length of the shuttle conveyor during the transfer process. It also ensures that there is a long drop from one conveyor to another thereby removing snag and jam points.

Sliding conveyor in use feeding 4 ironers

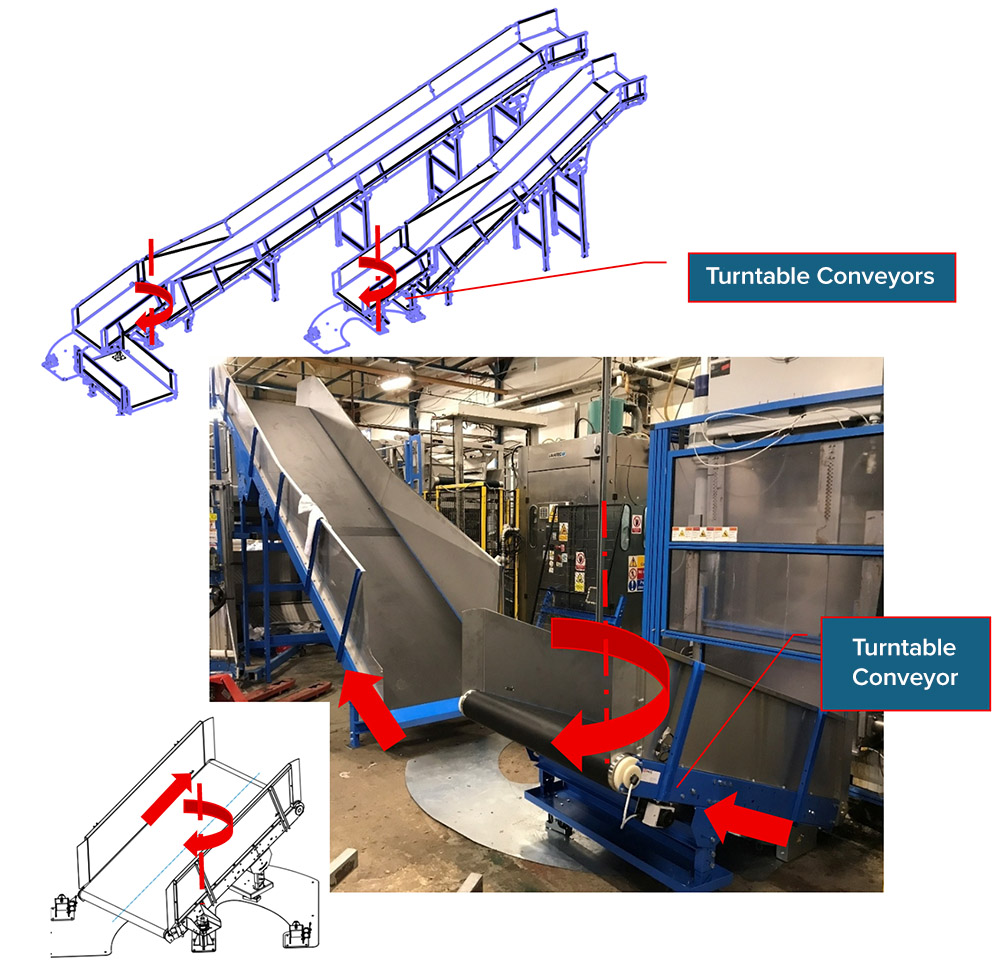

Space restricted Cake conveyors with tortuous travel path

Moving 80, 90 or 100Kg cakes of wet linen between the cake press and cake breakers can be difficult because of access restrictions – especially in legacy buildings where there can be many obstructions resulting in the need for conveyors to twist and turn as they move the cakes.

A novel turntable type belt conveyor available from Amber Industries is designed to help solve this issue. The conveyor is built from a horizontal or inclined belt conveyor – often not much longer than the cake itself - mounted on a motorised turntable. The turntable allows the floor space to be greatly reduced compared to other methods, e.g. the use of belt bends. It also allows the cake to be elevated as it turns which can be very useful when the cake must be delivered to a destination well above floor level and space is unavailable for an elevator.

An added benefit of using an inclined conveyor like this is that the cake may be dropped over a waterfall as it leaves the turntable which helps with the breakup process.