Belt Curves for Intralogistics

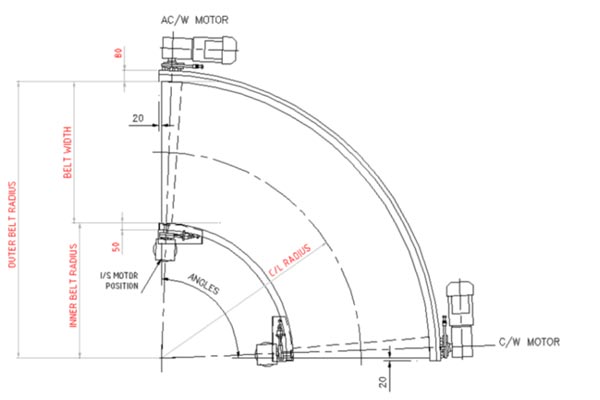

The Gramac Quartz division of Amber Industries Ltd has designed and manufactures the TSTR100 range of powered belt curve conveyors which includes a number of sizes and formats specifically suited to intralogistics applications, i.e. warehouses, post and parcel sorting depots, and e-fulfilment centres etc. The table below shows the most common sizes for the Intralogistics industry. Further sizes are also available in the TSTR100 range which can be seen in the table in the ‘Belt Curves for Industry’ section.

Standard TSTR100 Sizes for Intralogistics Applications

| Inner Radius(mm) | Belt Widths (mm) | Standard Angles ( ° ) |

|---|---|---|

| 800 | 600, 700, 800, 900 | 30°, 45°, 60° 90°,180° |

| 1000 | 900, 1000, 1100, 1200 | 30°, 45°, 60° 90°,180° |

| 1200 | 1000, 1100, 1200, 1300 | 30°, 45°, 60° 90°,180° |

| 1500 | 1100, 1200, 1300, 1500 | 30°, 45°, 60° 90°,180° |

Safe & Easy Maintenance

- TSTR100 Belt Curves are safe and easy to maintain without excessive manual handling or the need for any special tools

- The moving part guards are lightweight for easy removal. Heaviest component is normally the Motor unit at up to 35 Kg

- Sealed for life bearings minimise the need for lubrication

- Belts can be changed in under 20 minutes

- Every curve has an O&M manual with detailed explanations of the recommended periodic maintenance inspections