Introduction to Gramac Quartz Belt Curves

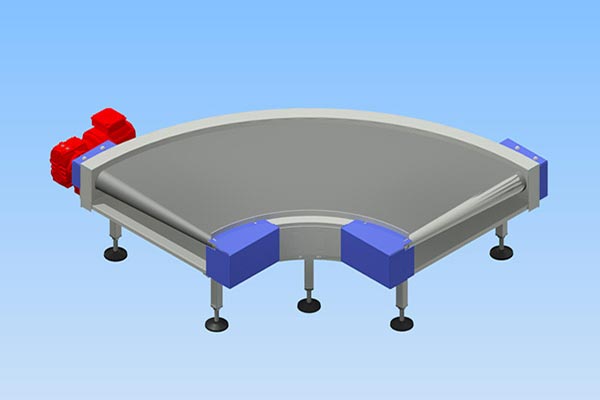

Belt Curves, Belt Turns or Powered Belt Curves are generally considered to be a specialist type of belt conveyor and as such they are supplied by a specialist manufacturer. Gramac Quartz is the division of Amber Industries Ltd which has specialised for over 30 years in the manufacture of Belt Curves for many different combinations of load duty, arc and width formats. These time served belt curves are marketed under the Gramac Quartz brand name.

Belt Curves for the Intralogistics Industry

Amber Industries range of high speed, friction driven and robust belt curves are designed to reliably give the long service life demanded by the Intralogistics Industry.

Belt Curves for the Manufacturing & Processing Industries

Gramac Quartz belt curves are used in many Industries where precise and fast changes in direction of conveyed products is required. Examples are in bulk material bagging lines (e.g. cement, aggregates, compost etc), car component production lines, food packaging lines and laundries to name just a few.

Belt Curves for Airport Baggage Handling Systems

Gramac Quartz belt curves have a proven track record over 30 years of longevity and reliable operation in airport baggage handling systems around the world from remote islands in the Pacific to the largest and busiest airports.

TR200 Heavy Duty Belt Curves

The design of the TR200 range belt curves gives them a higher load capacity of 200 Kg/m (measured along the C/L) and perhaps more importantly allows a thicker belt to be fitted around the 200mm max diameter end pullies.

Product Design Advantages, Features & Benefits

Gramac Quartz Belt Bends have a proven track record of longevity and reliable operation around the globe in a variety of environments and industries.

Belt Curve Technical Data & Specifications

Applicable Standards for All Belt Curve Models