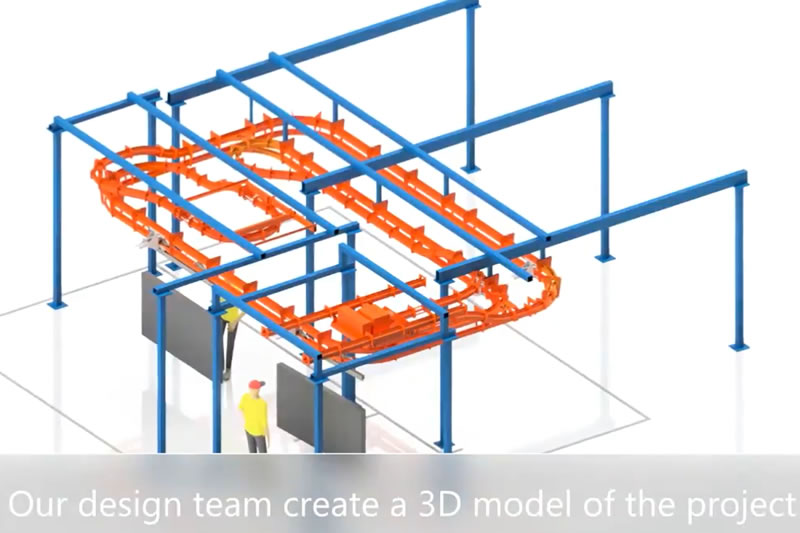

Composite Manufacturing Overhead Conveyor Design To Installation

1

From design to installation, Amber Industries completed a AT100 power and free system for a major composites supplier. The MCM Autotrack range of power & free conveyors (AT50, AT100, AT500M and AT600) are specifically designed with the flexibility to allow product loads to be directed along different routes within an overall conveyor system. This means that each specific product type can be identified (electronically or with mechanical flags) and automatically routed to specific destinations, e.g. process plant lines, assembly lines, storage zones, inspection and unload stations etc., in any desired sequence.

Product loads can be stopped at almost any position within a power & free conveyor system to allow various manufacturing operations to be performed. Product loads can also be stored within a buffer storage area enabling production imbalances and the impact of shift changes to be smoothed out. Speed changes through designated zones of a system can be incorporated to match the requirements of particular in-line processes. Powered ‘Drop sections’ can be built into a power & free conveyor system to raise or lower product loads to facilitate certain operations or loading and unloading of larger products.

Other Articles

Amber Industries Exhibiting At Paint Expo 2026

18

Technical Data For Overhead Chain Conveyors Published

20

Season's Greetings From Amber Industries

15

Control Systems For Overhead Conveyor Automation

4

MCM Powertrack Range From Amber Industries

4

MCM Freetrack Conveyor Systems In Focus

13

MCM Dualtrack Inverted Conveyor System

1

Laundry Conveyors by Amber Industries

13

MCM Powertrack Overhead Monorail Conveyor Systems

11

Belt Curves for Airport Baggage Handling Systems

2