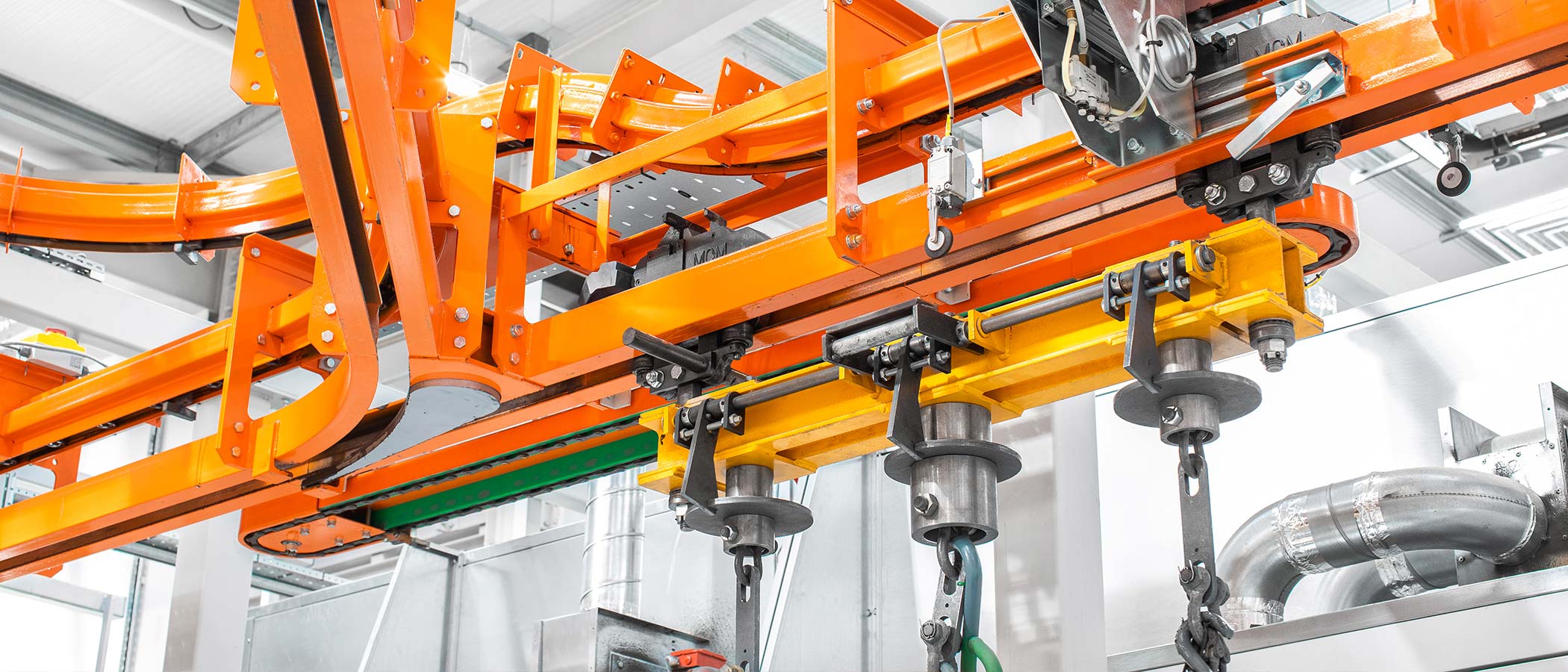

MCM Overhead Conveyors

The principle of overhead chain conveyors is that they utilise a continuous powered chain running in a track. Fitted to the chain at regular intervals are single pendants from which the products to be carried are suspended either directly or by means of load-bars or purpose made carriers. Instead of pendants ‘dogs’ may be fitted to the chain in order to push trolleys along a second track normally mounted underneath the chain track. The products to be conveyed are in turn suspended from the trolleys. This type of overhead conveyor system is termed ‘Power & Free’.

The MCM Conveyors division of Amber Industries Limited has developed and manufactures its own comprehensive and high quality range of light, medium and heavy duty overhead conveyor systems.

The modular design of these systems, combined with a range of standard accessories such as a selection of different radii horizontal and vertical curves, spinners, indexers, automatic load - unload units etc., enables them to be easily configured to suit the most complex routing and layout requirements of any manufacturing and assembly processes. Installation is quick and easy and the modular design also allows later extensions and system rearrangements to be undertaken.

MCM Overhead Conveyors are marketed under one of five trade names depending on the type of system.

MCM Autotrack - Power & Free Conveyor Systems

A range of ‘power & free’ overhead chain conveyors designed with the flexibility to allow product to be directed along different routes with in the same system depending upon the sequence.

MCM Powertrack

A range of ‘monorail’ overhead chain conveyors suitable for handling a wide range of product in many industries. They come in two types: the ‘enclosed chain’ type for medium loads up to 100Kg and the ‘open chain’ type for heavier loads up to 500Kg.

MCM Sidetrack - Monorail Conveyor Systems

A range of ‘monorail’ overhead chain conveyors with the track rotated through 90 degrees so that any contamination from the chain, such as lubricating oil is prevented from falling on to the product.

MCM Dualtrack - Inverted Conveyor Systems

The MCM Dualtrack range of conveyors, DT100 & IAT100 P&F are comprised of a powered bi-planar chain in an enclosed track with a secondary stabilising rail forming another track, hence 'dual' tracks. They are very stable making them suitable for accurate positioning of the product. The IAT100 system is a true inverted Power & Free Chain Conveyor System.

MCM Freetrack - Conveyor Systems

MCM Freetrack conveyor systems use the standard track components available in the Powertrack range, however instead of fitting a chain powered by a motorised drive unit, free running trolleys (bogies) are inserted into the system from which the product load is suspended.

MCM Overhead Chain Conveyors - Operating Principles

The principle of overhead chain conveyors is that they utilise a continuous powered chain running in a track. Fitted to the chain at regular intervals are pendants from which the products to be carried are suspended either directly or by means of load-bars or purpose made carriers.

Control Systems for Automation

Just as crucial to the efficient functioning of any conveyor system as the mechanical hardware is its control system. Depending upon the complexity of the conveyor system, control systems can range from simple start stop boxes to multiple control panels incorporating state-of-the-art PLCs and HMI’s regulating numerous input and output devices.

Overhead Chain Conveyors - Technical Data

Overhead Chain Conveyors - Technical Data