Conveyor Maintenance & Repair Services

With its own team of skilled installation and service engineers, supplemented by a nationwide network of professional site services contractors, Amber Industries Ltd. offers the full complement of support services needed to ensure minimum downtime and the maximum reliable operating lifespan of our client’s conveyor systems.

Our engineers and service partners are all experienced technicians, thoroughly trained on our conveyor products and fully equipped to carry out the tasks required to deliver a high quality service. A dedicated Service Coordinator located at our head office prioritises and allocates their work according to client’s specific needs and demands, thereby assuring an appropriate and timely response.

To arrange one of the following service packages simply contact our head office and ask for the service desk.

Service Packages

1. Planned Service Visits

This is a preventative maintenance package designed to identify and rectify potential failures in the equipment before they occur and cause complete breakdowns. Depending upon the size, complexity and intensity of use of the conveyor system one or more service visits per year are scheduled at regular intervals. At each visit the engineer(s) thoroughly inspect the conveyor equipment to check for correct operation, making minor adjustments to such items as the chain or belt tension, drive unit settings, lubrication, pneumatics etc. as may be necessary. A detailed report is then submitted to the client in which any signs of wear or damage are highlighted and remedial actions with timescales are recommended.

2. Call Outs

Should a client’s conveyor system become damaged or break down for whatever reason Amber Industries Ltd’s service organisation will respond urgently to a request for assistance. Our aim will always be to fix the problem and get the conveyor system up and running again at the earliest practical opportunity. N.B. Planned Service Visit clients receive the benefit of priority for call outs and at reduced rates.

3. On-Site Training

Training sessions in the operation and maintenance of a conveyor system can be provided at the client’s premises for production and maintenance personnel.

4. Chain Change-Outs

The bi-planar chains within overhead chain conveyors inevitably stretch with use over time. A tiny fraction of a millimetre of wear per link, even when properly lubricated, can add up to a substantial extension of the chain overall. When this extension can no longer be taken up by the tension unit or the chain doesn’t mesh properly with the drive unit, it is time to fit a new chain. Our service engineers are practised in undertaking conveyor chain change-outs quickly so as to cause the minimum downtime of the overhead conveyor system.

5. Condition Surveys and Refurbishments

The reliable operating lifespan of a conveyor system can often be extended by refurbishing it. However, prior to undertaking any refurbishment works it is a good idea to define the scope of the refurbishment works required to restore the conveyor system to good working order. Amber Industries Ltd. offers a complete Condition Survey service in which the conveyor system in question taken out of operation for a period and all of its components are examined in fine detail to establish whether they are still serviceable or whether they need to be replaced, e.g. measurements of track thickness are taken at regular intervals around a circuit to determine wear, chain extension is measured and the working and condition of control devices and electrical wiring is closely inspected. A report is then prepared in which the scope and the programme of refurbishment works are proposed along with a schedule of costs and an analysis of the expected benefits.

6. Conveyor Extensions and Modifications

Many of our conveyor systems are capable of being extended or modified in order to adapt to the changing requirements of the end-users operations. Our engineers will be pleased to give advice about how a particular conveyor system might be re-configured or expanded to accommodate operational developments.

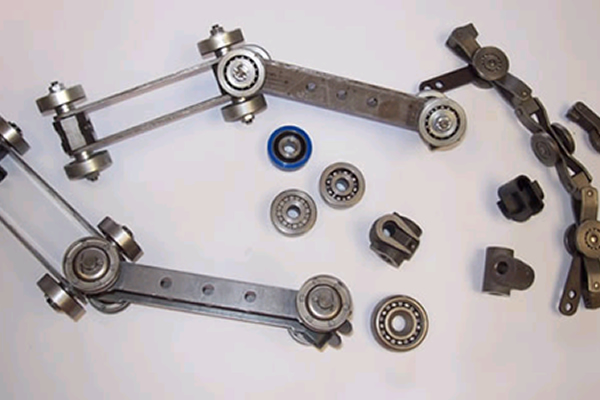

Conveyor Spares

Conveyor Spares

Conveyor Spares