Control Systems for Automation

Just as crucial to the efficient functioning of any conveyor system as the mechanical hardware is its control system.

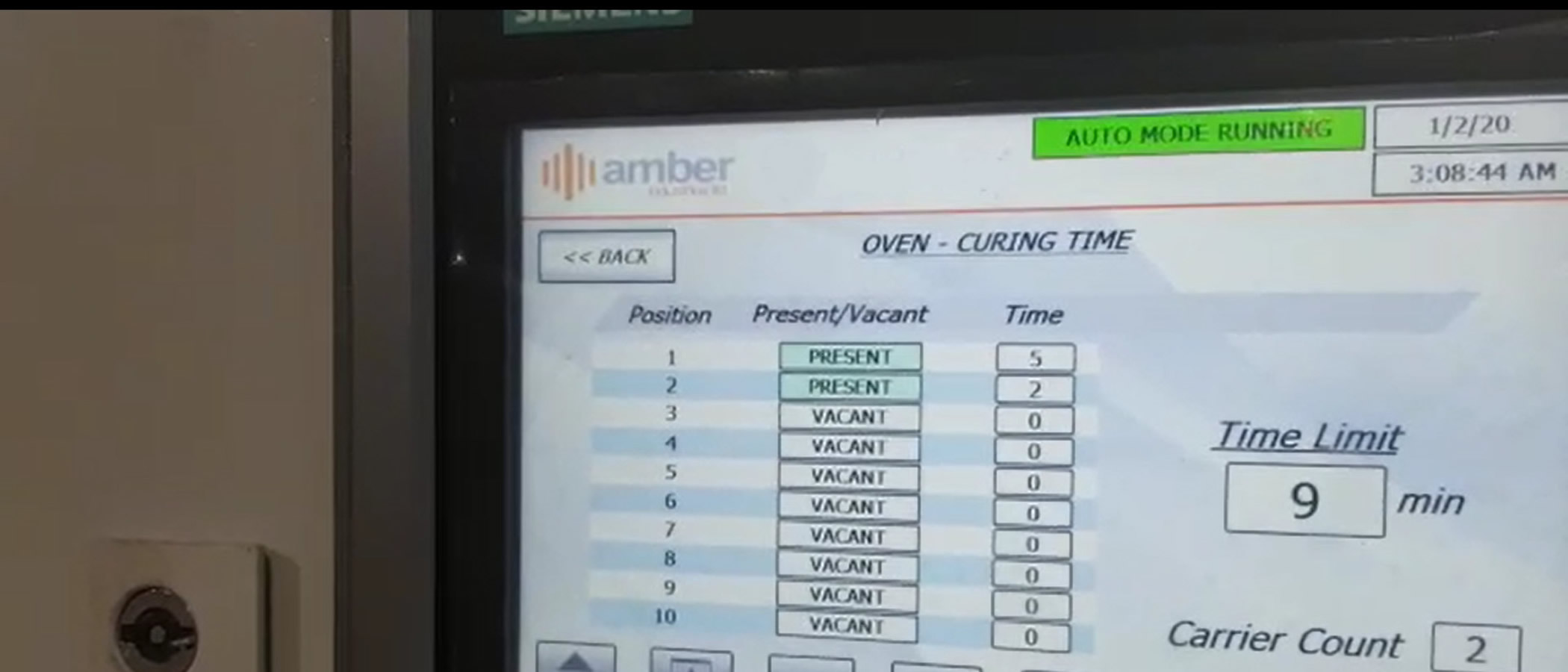

Depending upon the complexity of the conveyor system, control systems can range from simple start stop boxes to multiple control panels incorporating state-of-the-art PLCs and HMI’s regulating numerous input and output devices, e.g. photocells, sensors, RFID, bar-code scanners, drive units etc. These provide a high degree of machinery control and enable the materials handing / conveying processes to be fully automated making them more efficient with resultant gains in productivity and ROI. Other features such as product tracking, system diagnostics, maintenance alarms and remote monitoring can be incorporated.

The ability of modern PLC’s to communicate with each other means that a conveyor system can be integrated into larger automated process plants if required.

More often than not these control systems are designed with one or more HMI built into then, thus the operator has a graphical representation of the operation and the ability to interrogate and diagnose faults early. Management data can also be provided e.g. error logging, throughput, product traceability, system downtime etc.

Our controls systems team have the know-how to design and implement bespoke control systems for any size and complexity of automated conveyor or material handling system. In the process we will ensure that the performance of all hardware is optimised. PLC manufacturers we have experience with include Siemens, Rockwell/Allen Bradley, Mitsubishi and Omron.