Amber Industries engineering team have the ability to design bespoke handling equipment to make a conveyor system function optimally.

Beam Unloader

Amber Industries designed and manufactured a device for automatically unloading racking beams from an overhead chain conveyor after they had been through the paint plant and laying them flat on a belt conveyor for onward travel to a despatch area.

Laundry Conveyors by Amber Industries Ltd.

Amber Industries is experienced in engineering and delivering a full range of conveyor systems for moving linen around laundries.

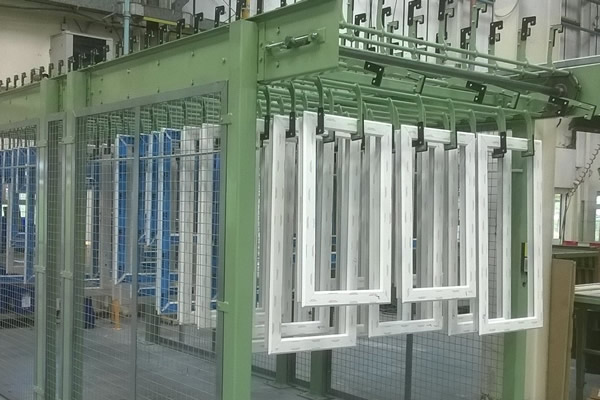

Storage Unit

Above is an end of production line cooling and storage unit for UPVC window frames.

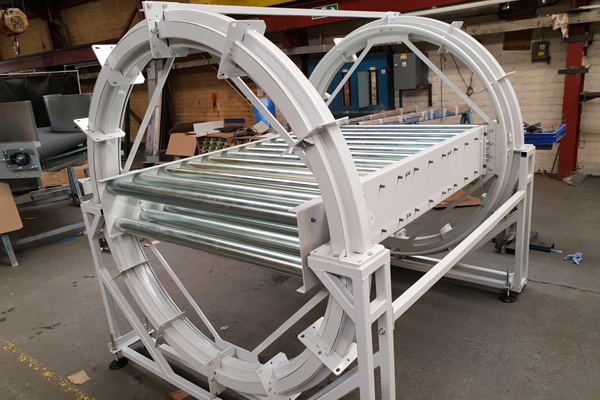

Turnover Unit

Amber Engineers designed, manufactured and installed this device for turning over delicate sheet materials to allow both sides to be surface treated.

Package Sorter

Originally designed for high speed sorting of returned library books to facilitate re-shelving them. The equipment can be used for sorting any type of small package. It can easily be configured to have 3,4,7,9 or 11 or more outlets.

Pet Food Distribution Line

Amber Industries engineers were commissioned to design, manufacture and install a stainless steel conveyor line to take sausage shaped packages of processed meat for pet food from the processing machine to the packing area.

Lifting Elevator Units

In warehouses where space is often at a premium and there are often two or three levels of mezzanine floors, a means of lifting and lowering palletized product loads between the floor levels is required.